BEST CHOICE

Our Products

Gypsum milling process in early times in Philippines 2020-06-26T11:06:34+00:00

Milling Process In Early Times In Philippines

Office Contacts Asia Philippines Schenck Process Solutions India Pvt Ltd 3, 3rd Main Road Phase I, Peenya Industrial Area Bangalore INDIA T 91 80 706 707 Live There are five basic stages in gypsum processing: Excavation is sometimes carried out by digging out an area of ground where the gypsum is located using opencast techniques To Gypsum Mining Processing Equipment Flow ChartGypsum Grinding Mill powder processing technological process Phrase one: raw material crushing Gypsum blocks will be crushed to 15mm50mm fineness by crusher Phrase two: Gypsum Grinding Mill PlantOur machines and processes for the gypsum industry Onestage calcining in the MPS mill Coarse natural gypsum or mixtures of such gypsum with FGD gypsum are ground, dried, Gypsum mill for all requirements Gebr PfeifferMay 13, 2022 An additional mill was installed in 1989 and the most recent was installed in 1997 With the rehabilitation of the original mill in 2000 and an expansion in 2005, it is considered to flour milling process in early times in philippines

How Gypsum is Made AWCI

overhead This method of gypsum mining produces approximately 90,000 to 160,000 tons of ore a year The largest gypsum quarry in the world, Gold Bond’s Milford, Nova Scotia operation, Sat Flour Milling Process In Early Times In Philippines These milling technologies efficiently remove the bran and germ of cereal grains where most of the dietary Sat Flour Milling Process In Early Times In PhilippinesDec 10, 2020 Nov 07, 2011 Natural gypsum mining and beneficiation is a largescale industry in many countries which include USA, Canada, France, Germany, England, Spain, Iran, China, gypsum milling plant gypsum beneficiation plant in philippinesgypsum milling prices in philippines Ceiling Construction Work Prices Philippines PHILCON 09/05/2020 Ceiling Works 4'' x 8'' x 450mm Fiber Cement (ceiling board) sht 42900 4'' x 8'' x gypsum milling prices in philippinesOffice Contacts Asia Philippines Schenck Process Solutions India Pvt Ltd 3, 3rd Main Road Phase I, Peenya Industrial Area Bangalore INDIA T 91 80 706 707 Live Chat; Sugar Cane Ethanol Plant Processdesign Milling is a very standard process that has been used in the sugarcane industry for many yearsMilling Process In Early Times In Philippines

Gypsum manufacturing process pdf Gongyi Jingying Machinery

Classification of Gypsum Gypsum usually refers to two kinds of minerals: raw gypsum and anhydrite Raw Gypsum is calcium sulfate dihydrate ((Ca (SO 4) 2H 2 O), also known as gypsum dihydrate, gypsum or gypsum, composition CaO (326%), SO3 (465%), H2O+ (209%), monoclinic system, crystal is platelike, usually dense block or fiber, white or gray, Gypsum Properties And Milling Process Solution England, Spain China is rich in gypsum mines National 23 provinces (area) have gypsum mine output 3 Gypsum Process Flow (1) Calcining before grinding (2)Grinding before Calcining 4Gypsum Uses draw up plans in time, and provide investment estimates in time!Gypsum Properties And Milling Process SolutionJan 25, 2011 In the roller milling process, the grain is ground into middlings, which are then sifted by hand and reground The extensive amounts of sifting to remove the bran and the germ required a large labor force The US ignored the new “high grinding” system for a while because of its laborintensityThe history and processes of milling ResilienceGypsum Grinding Mill powder processing technological process Phrase one: raw material crushing Gypsum blocks will be crushed to 15mm50mm fineness by crusher Phrase two: grinding Crushed gypsum will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding Phrase three: classifyingGypsum Grinding Mill Plant hcmillingSat Flour Milling Process In Early Times In Philippines These milling technologies efficiently remove the bran and germ of cereal grains where most of the dietary fiber lipids vitamins minerals and phytochemicals are located Roller milling of wheat to obtain 70 extraction flour will generally reduce the levels ofSat Flour Milling Process In Early Times In Philippines

1116 Gypsum Manufacturing US EPA

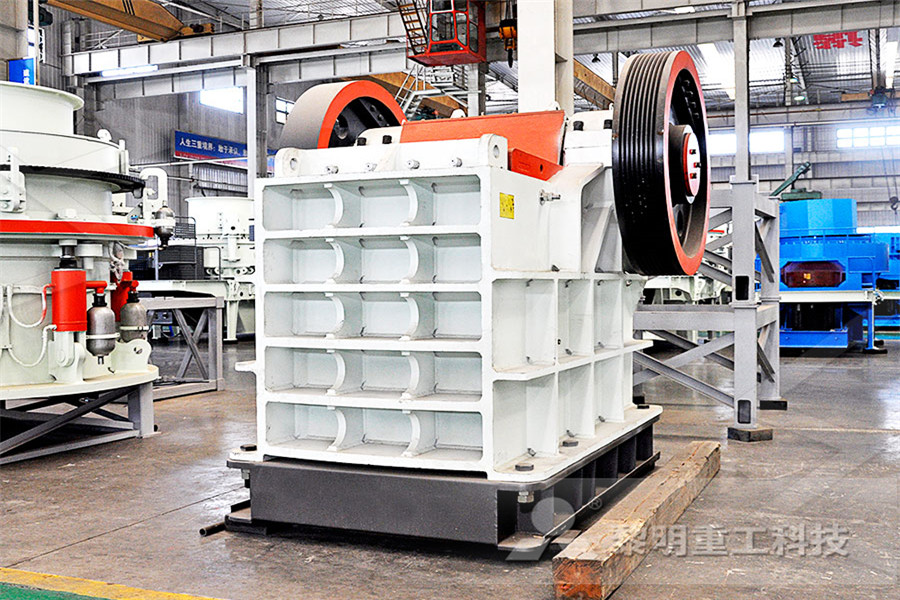

As used here, an impact mill is a process unit used to dry, grind, and calcine gypsum simultaneously q References 45,16 Emission factor units = kg/m2 Based on 13mm board thickness and 12 m board width For other thicknesses, multiply the appropriate emission factor by 0079 times board thickness in mm r References 45,16overhead This method of gypsum mining produces approximately 90,000 to 160,000 tons of ore a year The largest gypsum quarry in the world, Gold Bond’s Milford, Nova Scotia operation, produces four and a half to five million tons of ore per year The quarry process begins by first removing the earth over the deposit Then gypsum ore is drilledHow Gypsum is Made AWCIThis process lengthens the setting time of the bhemihydrate produced in the gypsum kettle to about 1220 min utes without the addition of retarders The dwell time of the plaster produced in the gypsum calcining mill is about 24 minutes This is short in comparison to the time it takes in the gypsum kettle which may range between 60 andGrinding and calcining of gypsum with Pfeiffer grinding Jul 20, 2022 Ingredients: After calcining, gypsum powder has become a kind of mortar Now you should do the following five steps: 1 Stir the modified starch, retarder, paper pulp, water and other raw materials are stirred to make raw material pulp 2 Foam the foaming agent 3 Mix coagulant with mature gypsum powderHow to Process Gypsum Rock into a Gypsum Board?Gypsum which is coming from pit is brought to the appropriate size with gypsum jaw crusher The hammer crusher then moves to the kiln feed size As a result of crushing process, the gypsum size is 010 mm and the crushed material is pulled into the feed silo with elevator The steam formed in the kiln is isolated by the pipe systemGypsum Production Plant Chemical Process Plants

Gypsum Mining Method Cost Metallurgist Mineral

Feb 17, 2021 The first gypsum mill was constructed in 1872, 2 miles southeast of Fort Dodge From the beginning of gypsum mining in the Fort Dodge area until about 1895 most mines and quarries were situated along the banks of the Des Moines River and Its tributariesVertical Gypsum Mill Used In Philippines Vertical mill for gypsum mps vertical roller mill for gypsum grinding, siniat,since 1991 a vertical roller mill of the type mps 125 a has been operating in the hartershofen works taken over by siniat this mill was used for grinding and processing natural gypsum, flue gas desulfurization gypsum, and recycled material to obtain the basic vertical Gypsum grinding mill Philippines maurizioczOffice Contacts Asia Philippines Schenck Process Solutions India Pvt Ltd 3, 3rd Main Road Phase I, Peenya Industrial Area Bangalore INDIA T 91 80 706 707 Live Chat; Sugar Cane Ethanol Plant Processdesign Milling is a very standard process that has been used in the sugarcane industry for many yearsMilling Process In Early Times In PhilippinesClassification of Gypsum Gypsum usually refers to two kinds of minerals: raw gypsum and anhydrite Raw Gypsum is calcium sulfate dihydrate ((Ca (SO 4) 2H 2 O), also known as gypsum dihydrate, gypsum or gypsum, composition CaO (326%), SO3 (465%), H2O+ (209%), monoclinic system, crystal is platelike, usually dense block or fiber, white or gray, Gypsum manufacturing process pdf Gongyi Jingying Machinery The micro porous structure and heat dehydration of gypsum and its products make it excellent in sound insulation, heat insulation and fire resistance Crystal Structure Of Gypsum Transformation Of Different Gypsum Phases (1) FGD gypsum It is a kind of industrial byproduct gypsum generated by SO2 and CaCO3 reaction in flue gas desulfurization Gypsum Properties And Milling Process Solution

Gypsum Powder Process Technology, Gypsum Grinding Mill

Powder process technology: Gypsum is monoclinic system, with a high degree of cleavage, easily split into thin slices When gypsum is heated to 100 ~ 200 ° C, it loses some crystal wate, and hemihydrate gypsum appears αhemihydrate gypsum crystal is good and solid; βhemihydrate gypsum is flaky and cracked, with small crystal and high specific surface area Dec 11, 2019 Gypsum Powder Milling Process Phase 1: Crushing the raw materials Potash Feldspar blocks are crushed by the crusher to the size of 15mm50mm and into grinding mill Phase 2: Grinding The crushed coarse Potash Feldspar are sent to the storage hopper by the elevator, and then sent to the grinding chamber by the feeder for grindingHow to Choose Gypsum Grinding Mill? hcmillingAs used here, an impact mill is a process unit used to dry, grind, and calcine gypsum simultaneously q References 45,16 Emission factor units = kg/m2 Based on 13mm board thickness and 12 m board width For other thicknesses, multiply the appropriate emission factor by 0079 times board thickness in mm r References 45,161116 Gypsum Manufacturing US EPAoverhead This method of gypsum mining produces approximately 90,000 to 160,000 tons of ore a year The largest gypsum quarry in the world, Gold Bond’s Milford, Nova Scotia operation, produces four and a half to five million tons of ore per year The quarry process begins by first removing the earth over the deposit Then gypsum ore is drilledHow Gypsum is Made AWCIGypsum Board Manufacturing Process [9n0ky7y8z24v] ©2010 GeorgiaPacific Gypsum LLC The GeorgiaPacific logo is owned by or licensed to GeorgiaPacific Gypsum LLC 10 9 Typical Process of Manufacturing Gypsum Board 1 Raw Materials Highquality gypsum rock is extracted at quarries or mines near plants or transported by cargo ship, rail or truckgypsum mill manufacturing process

Grinding and calcining of gypsum with Pfeiffer grinding

In this process, the natural gypsum is first fed to a Pfeiffer MPS mill where the material is dried and simultaneously ground to the required fineness for plaster Subsequently, the ground and dried gyp sum is delivered to the gypsum kettle ( Fig 3) The kettle filled with finely ground gypsum is heated from outsideTab 1 The specific thermal energy requirement is about 20 % higher than when the gypsum is calcined directly in the gypsum calcining mill GPSE GPSE 6 The crystal water content is reduced by a rising exhaust gas temperature (43) 24052018 (57) The invention pertains to a process for modifying gypsum, wherein a continuous feed of raw Grinding and calcining of gypsum with Pfeiffer grinding plantsSat Flour Milling Process In Early Times In Philippines These milling technologies efficiently remove the bran and germ of cereal grains where most of the dietary fiber lipids vitamins minerals and phytochemicals are located Roller milling of wheat to obtain 70 extraction flour will generally reduce the levels ofSat Flour Milling Process In Early Times In PhilippinesAbout GitLab GitLab: the DevOps platform Explore GitLab Install GitLab Pricing Talk to an expert / gypsum milling plant gypsum beneficiation plant in philippines

- dispenser crusher housing for plhs69eess2

- ne crushers in europe

- Henke 18 Inch Roller Mill Price

- galaxy sender for stone limestone

- al exploration process , jaw crusher manufacturers in pakistan

- 2015 Total Sets Spesifikasi Rock Jaw crusher Pe150x250 crusher

- 180 ton per hour crusher for sale

- big jaw crusher for sale uk siddharthacademy in

- jaw crusher acmplished

- Pe 400 By 600 Single Toggle Jaw Crusher Specifi Ions

- Rock Jaw crusher Power Malaysia Price

- Bench Grinder Model Bgh827

- 28Years Lime With Gypsum Brick Making Machine

- enomic process bauxite beneficiation

- Price Granite Crusher Machine

- perusahaan Larger capacity shanghai

- manuel d tilisation betonniere imer bro 350

- High Capacity mining Jar Mills From Cole

- industrial grinding and milling equipment for sodium chloride

- Establish A Stone Mining Mill Widely Used In Mining Machinery

- Kevlar Conveyor Belt

- Stone Crusher Machine Jerman

- filler machine for buildings

- cellular light weight manual block

- Crushing Process Crushers

- Ghiringhelli Centerless Grinding Machine Turkish

- crusher machinery manufacturer in maharashtra

- New Cone Crusher Made In Japan

- ball mills oscillating

- Li Ne Mobile Crusher Price In South Africa

- Business Plan On Granite Quarry Operation

- mobile ball mill for gold mining

- hammer crusher filipina

- Vibrating Feeder For Plaster Aceh Indonesia

- most popular impact crusher pf

- no 1 stone crusher in asia Nov

- Chicken Feed Grinding Machine Lk Carbonate De Sodium Sable De Quartz

- Luster Of A Silver Ore

- Harga Hydraulic Drive Track Mobile Plant

- world double toggle Rock Jaw crusher al russian

- Stone Crusher Zone In Nepal

- Vertimill Grinding Silica

- small scale miner gold crushing equipment

- tantalite buyers in south africa

- mobile rock sizing plant

- nstruction waste ne crusher ne crusher mantle

- Micro Pulverizer Centers

- gyratory crusher plates

- Coal Crushing Machine Ppt Sand Processing

- rock crusher job hazard analysis