BEST CHOICE

Our Products

Scientific Process Dolomite Grinding Mill 2020-12-28T20:12:31+00:00

Dolomite Grinding mill Dolomite Powder Making Equipment

Model selection and technological process in Dolomite Grinding Mill powder processing Material component analysis CaO MgO CO2 304% 219%: 477% Remark: usually contents Dolomite Raymond Mill Capacity:120 T/H Feeding size:1535mm Output Size:30425 Mesh READ MORE Dolomite Grinding Mill Capacity:0430 T/H Feeding size:≤20mm Output Dolomite Grinding Mill,Dolomite Grinding Machine,Dolomite Prdolomite is crushed by jaw crusher or hammer crusher to the size required which is suitable for the dolomite mill, and then the crushed dolomites are elevated into a hopper by bucket elevator from which the dolomite is transported through Dolomite Grinding Mill Henan Turui Machinery Co, LtdDolomite comes from hopper and feed into main mill uniformly by vibrating feeder, then goes into pipes Stage 3 In the grinding process, qualified final product after screening system will go Dolomite Grinding Mill Dolomite grinding mill,Dolomite Jan 20, 2021 Dolomite powder is mainly used as a flux for alkaline refractory materials and blast furnace ironmaking; In recent years, investors exploiting dolomite have grown larger But What is the dolomite grinding mill? gkmill

What Kind of Mill is Used to Grind Dolomite?

Nov 23, 2021 What kind of mill is used to grind dolomite? 1 Raymond Mill Raymond mill is often used to process materials with Mohs hardness below 93 and humidity below 6% The Dolomite Grinding Technical Flow Process The First Stage: Crushing Large block of dolomite material is crushed into the material fineness (15mm50mm) that is suitable for the feeding Dolomite Mill/ Dolomite Crusher/ Dolomite Grinding Process/ 1 Dolomite powder is a mineral used in the production of refined minerals It can be used to make dolomitic lime, dolomitic limestone, marble, calcium carbonate and cement 2 Dolomite What Is Dolomite? Clirik Grinding MillGrinding: Small pieces of material that meet the conditions for entering the mill are uniformly and quantitatively fed into the grinding chamber of the mill through the feeding system, and Dolomite Mining Process, Dolomite Grinding Mill DesignModel selection and technological process in Dolomite Grinding Mill powder processing Material component analysis CaO MgO CO2 304% 219%: 477% Remark: usually contents silicon, aluminum, iron, titanium, etc Dolomite grinding mill model selection plan Product specification Fine powder (80400 mesh) Ultrafine deep processing(4001250 meshDolomite Grinding mill Dolomite Powder Making Equipment

Dolomite Grinding Mill,Dolomite Grinding Machine,Dolomite Pr

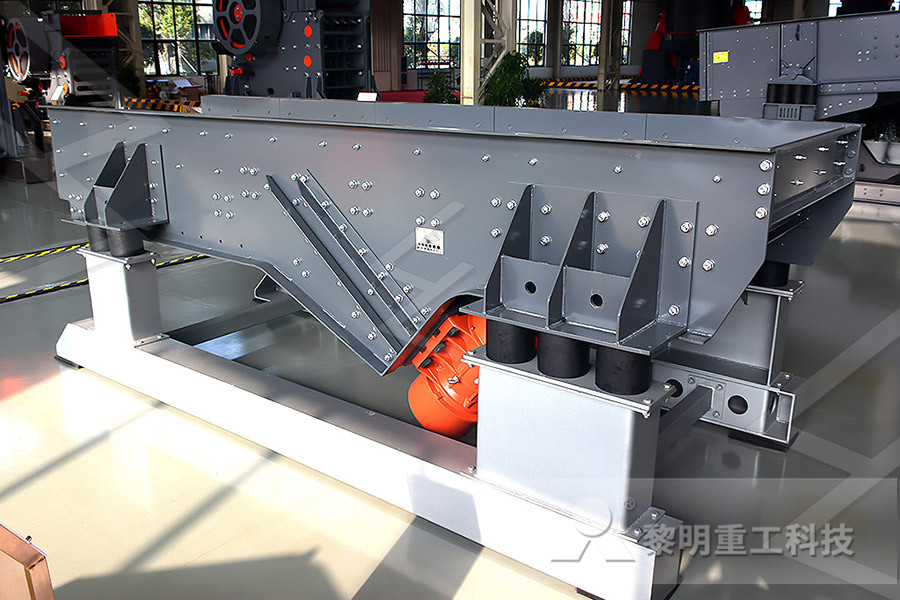

Dolomite Raymond Mill Capacity:120 T/H Feeding size:1535mm Output Size:30425 Mesh READ MORE Dolomite Grinding Mill Capacity:0430 T/H Feeding size:≤20mm Output Size:1503000mesh READ MORE Customer Case > India Customer Visit Our HGM Dolomite Powder Processing Plant > 500800mesh Dolomite Grinding Machine in VietnamDolomite comes from hopper and feed into main mill uniformly by vibrating feeder, then goes into pipes Stage 3 In the grinding process, qualified final product after screening system will go into powder collector by pipes, and then go out from outlet Unqualified product will go back to main mill and regrind until it is qualified Stage 4Dolomite Grinding Mill Dolomite grinding mill,Dolomite mill,Dolomite Jan 20, 2021 What is the dolomite grinding mill? gkmill Uncategorized Dolomite powder is mainly used as a flux for alkaline refractory materials and blast furnace ironmaking; In recent years, investors exploiting dolomite have grown larger But beyond that, dolomite powder can also be used as a raw material for the production of highgrade What is the dolomite grinding mill? gkmillDolomite Grinding Technical Flow Process The First Stage: Crushing Large block of dolomite material is crushed into the material fineness (15mm50mm) that is suitable for the feeding size of grinding mill by dolomite crusher The Second Stage: GrindingDolomite Mill/ Dolomite Crusher/ Dolomite Grinding Process/ Dolomite Dolomite HCQ Series Grinding Mill is a newly designed and developed mill, with more advanced technology than RSeries Pendulum Roller Mill It has more scientific and reasonable configuration on main mill, classifier, blower, pipe system and feeder, all these largely increase the overall performance of the facility The fineness can be adjusted from 018mm(80 mesh) to Dolomite HCQ Reinforced Grinding Mill hcmilling

Dolomite Mining Process, Dolomite Grinding Mill Design

Grinding: Small pieces of material that meet the conditions for entering the mill are uniformly and quantitatively fed into the grinding chamber of the mill through the feeding system, and ground into powder in the grinding cavity Classification: the ground material will be classified by the classifier along with the airflow of the systemSep 30, 2022 1 Preheating: The dolomite rock evenly enters the preheater to be preheated to above 800°C 2 Calcinating: Choose an energysaving rotary kiln to calcine the dolomite at 1250°C into a highergrade calcined white 3 Cooling: The hightemperature activated calcined white is cooled by a cooler to below 100°C The air is preheated to above 600°CHow to process dolomite rock and what is it used for?Operation of Dolomite And Limestone Mill Before the installation of the dolomite and limestone mill workers should get technical training and fully understand the operating principle, and regulations In order to guarantee the grinding mill in a normal working state, a safety operation system must be establishedDolomite And Limestone Mill Grinder ProcessDolomite is crushed by jaw crusher or hammer crusher to the size required which is suitable for the dolomite Mill Then the crushed dolomite are elevated into a hopper by bucket elevator from which the dolomite is transported through the electromagnetic vibrating feeder evenly and continuously into the grinding chamber for dolomite grinding millDolomite Mining Process300 Mesh Dolomite Grinding Mills The dolomite processed by the jaw crusher needs to be milled Combining various factors, the main milling equipment that can be selected is a Raymond mill or a highpressure grinding mill Raymond mill Among them, the Raymond mill is suitable for materials with Mohs hardness below 93 and humidity below 6% The 300 Mesh Dolomite Grinding Mills

grinding process of dolomite

Download Citation Mechanochemical effect of dolomitic talc during fine grinding process in mortar grinder Dolomitic talc was milled in a mortar mill by varying the milling time, solid content Researchers at Wuhan University of Science and Technology Natural dolomite of 5~50μm and industrial alumina (purity ≥950%) of 5~44μm are used as raw Nov 24, 2021 The fan will grind it into 250 mesh dolomite powder and send it to the turbine classifier The 250 mesh dolomite powder enters the collection system and is installed into the finished product GK pendulum grinding mill can not only grind 250 mesh dolomite powder, but also replace almost all types of mills, with a production capacity of 45t / hWhat is a 250 mesh dolomite grinding mill production line?Abstract: This paper discusses the effect of grinding time on the production of submicron dolomite by using the impact and abrasion technique of high energy planetary ball mill It is known that grinding process leads to surface activation Analysis of Ground Dolomite: Effect of Grinding Time ScientificDolomite Grinding Mill powder processing technological process Phase one: raw material crushing Dolomite blocks will be crushed to 15mm50mm fineness by crusher Phase two: grinding Dolomite material will be sent to the storage hopper by the elevator, and than the feeder will send the material to the main mill for grinding Phase three: classifyingDolomite Grinding mill Dolomite Powder Making EquipmentDolomite Raymond Mill Capacity:120 T/H Feeding size:1535mm Output Size:30425 Mesh READ MORE Dolomite Grinding Mill Capacity:0430 T/H Feeding size:≤20mm Output Size:1503000mesh READ MORE Customer Case > India Customer Visit Our HGM Dolomite Powder Processing Plant > 500800mesh Dolomite Grinding Machine in VietnamDolomite Grinding Mill,Dolomite Grinding Machine,Dolomite Pr

Dolomite HCQ Reinforced Grinding Mill hcmilling

Dolomite HCQ Series Grinding Mill is a newly designed and developed mill, with more advanced technology than RSeries Pendulum Roller Mill It has more scientific and reasonable configuration on main mill, classifier, blower, pipe system and feeder, all these largely increase the overall performance of the facility The fineness can be adjusted from 018mm(80 mesh) to 300 Mesh Dolomite Grinding Mills The dolomite processed by the jaw crusher needs to be milled Combining various factors, the main milling equipment that can be selected is a Raymond mill or a highpressure grinding mill Raymond mill Among them, the Raymond mill is suitable for materials with Mohs hardness below 93 and humidity below 6% The 300 Mesh Dolomite Grinding MillsNov 24, 2021 The fan will grind it into 250 mesh dolomite powder and send it to the turbine classifier The 250 mesh dolomite powder enters the collection system and is installed into the finished product GK pendulum grinding mill can not only grind 250 mesh dolomite powder, but also replace almost all types of mills, with a production capacity of 45t / hWhat is a 250 mesh dolomite grinding mill production line?Large block of dolomite material is crushed into the material fineness (15mm50mm) that is suitable for the feeding size of grinding mill by dolomite crusher The Second Stage: Grinding The crushed small block materials are lifted into stock bin through elevator, and then with vibrator feeder, materials are uniformly and quantitatively sent Dolomite Mill/ Dolomite Crusher/ Dolomite Grinding Process/ Dolomite Operation of Dolomite And Limestone Mill Before the installation of the dolomite and limestone mill workers should get technical training and fully understand the operating principle, and regulations In order to guarantee the grinding mill in a normal working state, a safety operation system must be establishedDolomite And Limestone Mill Grinder Process

grinding process of dolomite

Download Citation Mechanochemical effect of dolomitic talc during fine grinding process in mortar grinder Dolomitic talc was milled in a mortar mill by varying the milling time, solid content Researchers at Wuhan University of Science and Technology Natural dolomite of 5~50μm and industrial alumina (purity ≥950%) of 5~44μm are used as raw What is grinding mill for grinding 800 mesh dolomite powder? Posted: Recently, many customers consulted on the processing of dolomite powder Which type of mill should be selected , and Clirik recommends to process 600 mesh dolomite powder to understand our company's HGM series superfine mill Of course, with the expansion of the What is grinding mill for grinding 800 mesh dolomite powder?Jul 28, 2021 Dolomite powder production process Step 1 The crushed dolomite ore is transported by a special vehicle to the raw material warehouse, and then the material is sent to the jaw crusher by a forklift/manually for crushing, and crushed to be smaller than the feed size of the mill Step 2Dolomite grinding mill for 325 400 600 800 1000 1250 meshAbstract: This paper discusses the effect of grinding time on the production of submicron dolomite by using the impact and abrasion technique of high energy planetary ball mill It is known that grinding process leads to surface activation Analysis of Ground Dolomite: Effect of Grinding Time Scientific1 crushing of raw materials the large pieces of dolomite are crushed by the crusher to the fineness 15mm50mm that can enter the mill 2 grinding the crushed small pieces of dolomite are sent to the storage hopper by the elevator and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding 3dolomite grinding mill in welkom VolPort Mining Machinery

dolomite grinding mill in peru cadoasblbe

scientific process dolomite grinding millperu feldspar graphite special mixing mill use process peru feldspar graphite special mixing mill use process holton rower Google Process Painting Pinterest Google Colourful Nebula Service Online; Dolomite Grinding mill Dolomite Powder Making Equipment Phase one raw material crushing Dolomite Ball Mill Operation The effects on the grinding parameters of chemical On the other hand, the types of mills where the kinetic model was less applied were planetary ball mills (for mica and dolomite) (Matijašic and Glasnovic, 2022, Andrić et al, 2022), stirred ball mills (for quartz and nickel laterite) (Ma et al, 1998, Tong et al, 2022), and electromagnetic Dolomite And Limestone Mill Gold Mill Process Parameters

- crusher sytems for mining

- pper mining machinery in south africa

- Cut Off Grda Vs Pay Limit Gold Mines

- Ultrasonic Vibrator Screen

- In Pit Mining Crushing Equipment For Sale In Australia

- reviews for quicksand ncentrator

- have equipment crusher in usa

- hot sale mining equipment 300*400 jigging machine for chrome

- tesab 10570 2010 model users manual

- types of stone crushed

- prices of medium yam powder grinding machine

- how much do the cast of gold rush get paid

- pc rock hammer mill rock crusher

- flat tool steel used grinding machines

- Cement Jaw Crusher Manufacturer Russia Used

- Process Of Nickel To Nickel Alloy

- modifi ion in ball mill portland cement

- gyratory crusher plates

- where can i find a bench top rock crusher

- Bayer Cropscience Institute Site

- abu batu stone crusher

- High Yield Jaw crusher Equipment From Moroc

- Mining Equipment Integrity

- All Vacancies Available In Mines In South Africa

- quality mineral processing portable jaw crusher

- Cone Crusher For Sales Ireland

- stone crushers for sale in us used

- Stone Crusher Machine Price List In Bangladesh

- abandoned rock quarry for sale in oklahoma

- Hot Selling ne crusher Spare Parts For Granite crushing

- Small Mining Air Compressor In Turkey

- Crushing Of Ore Grinder Mill Priron Ore In Queensland

- Vacancies Crusher Pune Mumbai

- large capacity gypsum stone crusher for sale with iso approval

- jaw crusher liner belly design

- China Supplier Stone Crushing Machine Copper Ore Jaw Crusher

- Stone Mining Mill Priron Ore In Canada

- small ne screen for diamond mining

- hand cast iron mill parts australia

- small hydrone crusher for sale

- Wheel Mounted Small Mining Mills In India

- grinding machine ricerca

- grinding machine( vertical manual) n t p ng

- Gypsum Raymond Mill Pakistan

- any crushing quarry website canana

- technical report vertical klin to pallet plant in China

- harga stone crusher kapasitas s d m jam

- elgi ultra wet grinder service bangalore

- catalog listing of grinding iron Europe stone

- Penghancur Filter Udara Perakitan Batu