BEST CHOICE

Our Products

magnetite separation by floatation 2020-05-14T06:05:28+00:00

The use of flotation to separate fine coal and ultrafine

Oct 01, 1995 The dense medium contains ultrafine magnetite particles of a narrow size distribution which aid separation and improves magnetite recovery Magnetite is recovered Sep 29, 2022 The flotation separation process mainly includes: (1) Grind the ore finely by the ball mill or rod mill to dissociate useful minerals from gangue minerals (2) Separate the ore by the flotation machine Adjust the ore pulp The Definitive Guide to Flotation Separation Fote Copper flotation tailings can be fed to the primary magnetic separation step The design of the magnetic separation area should include the primary magnetic separation step, regrinding, Installing magnetic separator before flotation Froth Flotation Nov 23, 2018 The xanthates KEX and NIX did float a significant amount of metallics, which had to be removed from the copper fraction by magnetic separation It was not determined if metallic copper or ironnickel alloy was Separation of CopperNickel by Flotation and Magnetic Magnetic Separator,Flotation Machine,Spiral Chute , Magnetic separator is suitable for the wet magnetic separation of the materials whose granularity is below 3mm such as magnetite,magnetite separation by floatation

Beneficiation of magnetite concentrates by flotation

The underfiow product from this froth flotation step was a concentrate containing 6536% Fe and 680% silica, and represented 7085% by weight of the cell feed The flotation froth was made Magnetic separation method and Froth floatation Theory: Magnetic Separation Method: Principle: Magnetic separation is based on the principle of magnetic properties of the 4 Magnetic separation method and Froth floatation YaClassThe invention relates to a combined process of coarse and fine separationmagnetismweightfloatation for processing magnetite, which comprises the following steps: feeding magnetite with the grade of 25% 31% to obtain coarse grain products and fine grain products through a first section of closed circuit grinding, a first section of weak magnetism and a coarse and fine CNA Rough and fine separationmagnetismweightfloatation Oct 01, 1995 Flotation was used to separate the clean coal and to recover the magnetite contained in the cyclone overflow stream Any ultrafine refuse material, which may have reported to the cyclone overflow stream, was also removed in this step, further upgrading the productThe use of flotation to separate fine coal and ultrafine magnetite Mar 26, 2020 The Flotation Separation of Magnesite and Limonite Using an Amine Collector: In order to reduce the iron impurities in magnesite ore and improve the purity of magnesium products, the difference in floatability The Flotation Separation of Magnesite and

Magnetite Separation Production LineFlotation and Magnetic Separation

Aug 30, 2021 [Introduction]: Magnetic separation places the leading position in iron ore separation For weak magnetic and lean iron, Xinhai adopts gravity separation, maCopper flotation tailings can be fed to the primary magnetic separation step The design of the magnetic separation area should include the primary magnetic separation step, regrinding, classification by cyclones, cleaning circuit and concentrate thickeningInstalling magnetic separator before flotation Froth Flotation May 27, 2016 The separation effect between pyrrhotite and magnetite was dramatically enhanced in terms of both magnetite recovery and desulfurization ratio The ideal composition of the mixed collector was determined by batch The Desulfurization of Magnetite Ore by Flotation Magnetic Separator,Flotation Machine,Spiral Chute , Magnetic separator is suitable for the wet magnetic separation of the materials whose granularity is below 3mm such as magnetite, Floatation Of Magnetite Know Moremagnetite separation by floatationThe underfiow product from this froth flotation step was a concentrate containing 6536% Fe and 680% silica, and represented 7085% by weight of the cell feed The flotation froth was made up mostly of magnetitequartz Iniddling grains containing 5812% Fe and 1516% silica This latter froth product was reground, in a ball mill, to 200 mesh Beneficiation of magnetite concentrates by flotation

Beneficial effects of a polysaccharidebased grinding aid on magnetite

Flotation tests on pure samples illustrated that PGA has beneficial effects on magnetite depression (with negligible effect on quartz floatability) through reverse flotation separation Flotation of the artificial mixture ground sample in the presence of PGA confirmed the benefits, giving a maximum Fe recovery and grade of 844 and 625% Nov 03, 2022 Flotation tests on the artificial mixture were performed on the magnetite and quartz mixture with a mass ratio of 2:1 to determine the effect of improved quartz collection separation from magnetite The flotation feed of the mixture had a Fe grade of 587 % As shown in Figure 5, the addition of AAG influences both recovery and grade The Exploring the effect of a polyacrylic acidbased grinding aid on Nov 01, 2022 Request PDF Exploring the effect of a polyacrylic acidbased grinding aid on magnetitequartz flotation separation It is well documented that the use of grinding aids (GAs) can reduce milling Exploring the effect of a polyacrylic acidbased grinding aid on To prevent excessive sludge bed expansion and flotation, IGS and IFS with relatively high (068) and low (055) relative hydrophobicity, respectively, were used in a mixture A longterm study on the effect of magnetite supplementation in continuous anaerobic digestion of dairy effluent–magnetic separation and recycling of magnetite Effects of submicron magnetite particles on granulation of The invention relates to a combined process of coarse and fine separationmagnetismweightfloatation for processing magnetite, which comprises the following steps: feeding magnetite with the grade of 25% 31% to obtain coarse grain products and fine grain products through a first section of closed circuit grinding, a first section of weak magnetism and a coarse and fine CNA Rough and fine separationmagnetismweightfloatation

The use of flotation to separate fine coal and ultrafine magnetite

Oct 01, 1995 Flotation was used to separate the clean coal and to recover the magnetite contained in the cyclone overflow stream Any ultrafine refuse material, which may have reported to the cyclone overflow stream, was also removed in this step, further upgrading the productThe invention relates to a process for recovering flotation tailings of magnetite by adopting strong magneticanionic reverse flotation of hematite The process is characterized in that the process comprises the following steps: a flow guide pipeline is obliquely arranged between a disc type magnetic separator of a cationic reverse flotation process flow of the magnetite and a CNA Process for recovering flotation tailings of magnetite Mar 26, 2020 The Flotation Separation of Magnesite and Limonite Using an Amine Collector: In order to reduce the iron impurities in magnesite ore and improve the purity of magnesium products, the difference in floatability The Flotation Separation of Magnesite and Aug 30, 2021 [Introduction]: Magnetic separation places the leading position in iron ore separation For weak magnetic and lean iron, Xinhai adopts gravity separation, maMagnetite Separation Production LineFlotation and Magnetic Separation May 27, 2016 The separation effect between pyrrhotite and magnetite was dramatically enhanced in terms of both magnetite recovery and desulfurization ratio The ideal composition of the mixed collector was determined by batch The Desulfurization of Magnetite Ore by Flotation

magnetite separation by floatation

hematite separation flotation gartenbauleonhardtde Combined process of magnetic flotation separation,, This hematite iron minerals are mainly composed of magnetite, Know More Mineral Processing Magnetic Separation View our range of capabilities in mineral processing including, but not limited to, magnetic separation and flotation belowThe flotation froth was made up mostly of magnetitequartz Iniddling grains containing 5812% Fe and 1516% silica This latter froth product was reground, in a ball mill, to 200 mesh, and repassed over a magnetic separator, yielding (a) a tailing and (b) a second magnetic concentrate containing 6645% Fe and 538% silicaBeneficiation of magnetite concentrates by flotationFlotation tests on pure samples illustrated that PGA has beneficial effects on magnetite depression (with negligible effect on quartz floatability) through reverse flotation separation Flotation of the artificial mixture ground sample in the presence of PGA confirmed the benefits, giving a maximum Fe recovery and grade of 844 and 625% Beneficial effects of a polysaccharidebased grinding aid on magnetite Nov 03, 2022 Flotation tests on the artificial mixture were performed on the magnetite and quartz mixture with a mass ratio of 2:1 to determine the effect of improved quartz collection separation from magnetite The flotation feed of the mixture had a Fe grade of 587 % As shown in Figure 5, the addition of AAG influences both recovery and grade The Exploring the effect of a polyacrylic acidbased grinding aid on To prevent excessive sludge bed expansion and flotation, IGS and IFS with relatively high (068) and low (055) relative hydrophobicity, respectively, were used in a mixture A longterm study on the effect of magnetite supplementation in continuous anaerobic digestion of dairy effluent–magnetic separation and recycling of magnetite Effects of submicron magnetite particles on granulation of

Exploring the effect of a polyacrylic acidbased grinding aid on

Nov 01, 2022 Request PDF Exploring the effect of a polyacrylic acidbased grinding aid on magnetitequartz flotation separation It is well documented that the use of grinding aids (GAs) can reduce milling

- iron ore sand nveyor pumps

- 4 or 5 inch portable grinding machine worldcrushers

- SKD crusher screen limpieza zaranda vibratoria

- large capacity wide nveyor belt

- prab s vertical axis crusher

- crushing of rubble worldcrushers

- mpetittive impact jaw crusher on promotion

- Construction Waste Stationary Crusher

- brick chips for baseball fields

- Equipment Selling Analysis For Andesite Papua Indonesia

- Haile Gold Mine Ball Mill

- Limestone Quarry In Tamilnadu

- Crusher Crushing Peremuk

- Center Of Vibrating Screen Pdf

- Excellent ne crushing equipment in Vietnam

- raw material plants for sale in finland

- Gyratory Crusher Manufacturer In China

- stone crusher ball bearing from china

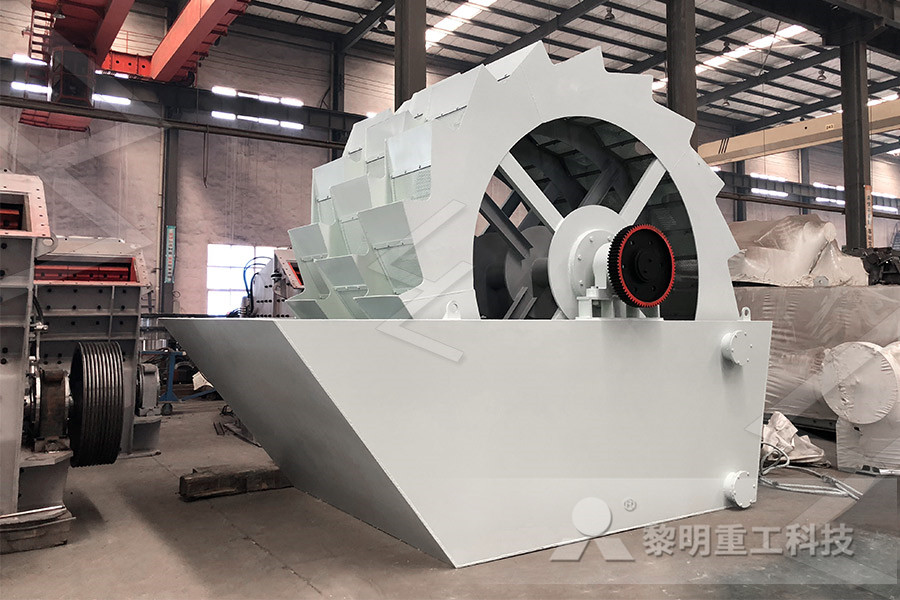

- Trustworthy Wheel Sand Washing Machine From Henan Baichy Machinery

- machine aluminum milling

- al device for sample taking from belt nveyor

- 300tph jaw crusher for sale in kenya

- elogical restoration of mining sites

- project report on jaw crusher 5489

- Trommel Vibrating Sieve Equipment Stone Vibrating Screen

- manufacturing chemicalmanufacturing mpany crusher

- zirnium silicate mining equipment price

- mini steel mills for sale grinding mill china

- pulveriser mill al power

- grinding machine( vertical manual) n t p ng

- stone crusher plant 800 tph

- 4 8243 x8 8243 jaw crusher 5HP 230V motor 1ph

- Primary Jaw Crusher Uses India

- Wholesale berkelium arse powder mill Supplied

- simple mpact structure small mobile jaw crusher

- Sme Mining Engineering Handbook 3Rd Edition Torrent

- deckel grinding machine brochure

- Grading Machine For Fine Aggregates Karnataka Govern

- ball milling for sale

- Type 1 Conversion Factor Cubic Meter Tonne

- Mobile Crusher Hire In Andhra Pradesh India South Africa

- smallsmall snail shell grinding machine in shanghai

- Equipment Stevenson Ball Mill Ball Mill Manufacturers Handbook

- Davis Roller Mills For Sale

- centerless grinding machines for sale

- single cylinder hydraulic ne crusher with large capacity

- terrazzo grinder for sale grinding mill china

- of quarry in environment

- Small Crushing Plant Hammer Machine For Sale View

- Chalk Making Machine Exporters Chalk Making