BEST CHOICE

Our Products

raw mill of cement line 2020-12-01T21:12:49+00:00

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant Cement

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plant In the cement manufacturing process, raw mill in Raw meal grinding is a vital link in the cement raw material preparation process After the cement raw material is crushed, it will be sent into the raw mill for further grinding until a certain Raw Mill – Raw Mill In Cement Plant AGICO Cement Raw MillVertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plant Vertical raw mill is Vertical Raw Mill Cement Raw Mill Raw Mill In Cement PlantThe raw mill is able to grind coal, limestone and some other aggregate for cement production line Features Benefits Cement production line and cement equipments for Portland Raw Mill In Cement Line Crusher MillsRaw mill is mainly used in grinding raw materials and end products in cement plant Vertical Raw Mill For Sale Feed particle size: 070mm Production capacity: 3340 tons / hour Ultrafine Raw Types Of Raw Mill In Cement Plant Grinder Process

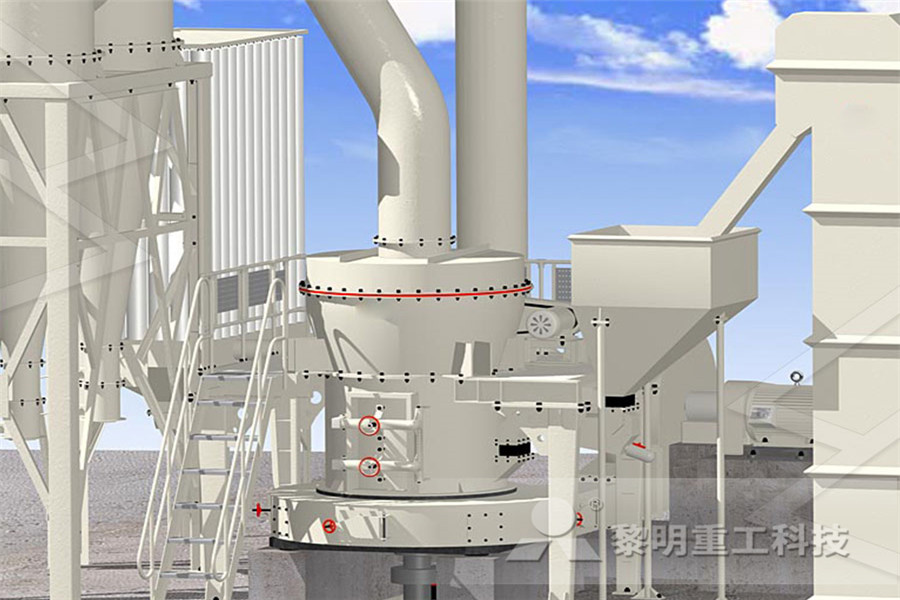

Vertical Raw Mill for Cement Raw Meal Grinding in

Vertical Raw Mill Feeding size: 35110mm Capacity: 12350t/h Motor power: 2553600kW Applications: It can be used for grinding limestone, gypsum, siliceous, coal and other Raw Mill Applied Materials: Cement raw material, Portland products, new building materials, refractories, granite, basalt, iron ore, limestone, calcite, quartz, and diabase, etc in cement, Raw Mill for Cement Plant Fote Machinery(FTM)Mix 1: Generalpurpose cement: 880% gray limestone, 89% clay, 22% sand and 09% millscale Mix 2: Sulfateresisting cement: 876% gray limestone, 52% clay, 50% sand and 22% Rawmill WikipediaJiangsu Pengfei Group Co,Ltd Address:Benjia,Ji,North Suburbs of Hai'an County,Jiangsu Province,PRC: Tel:0086513 : Fax:0086513 Cement plant raw mill of cement plant Mining Quarry Plantwhat is raw mill in cement line Know More The kiln line of Alesd II that is to be upgraded is a dry process one, with , to produce the clinker Alesd I , which then is grounded in the cement rawmill of cement line

Cement Mill Cement Ball Mill Vertical Cement Mill AGICO

In general, cement mill can both apply for dry cement production and wet cement production Cement mill in cement plant Commonly, there are three hot types of cement mill in the cement industry: cement ball mill, Raymond mill, and vertical cement mill AGICO Cement can supply cement mill according to your requirementsRaw mill is the grinding equipment applied in the raw material preparation processIn the wet process of cement production, raw materials should be ground into raw slurry with a water content of 30% – 40% While in the dry process of cement production, they will be ground into dry powder in cement raw millCement Mill Cement Grinding Machine AGICO Cement Grinding MillIn the traditional cement raw mill system, the cement ball mill system is more typical After technology modification, the vertical cement mill has obvious advantages compared with the cement ball mill, and it is suitable for the large cement production lineRaw mill in the cement plant greatwallcorporationroller press raw mill in cement cone crusher price, (roller press raw mill in cement) manufacturer, As a piece of Ore separating line equipment,raw material mill is widely used in beneficiation, Go to Product Center raw mill in cement plant CGM Grinding Plant, Raw mill in cement line,Vertical Raw mill for sale raw mill of cement line chinaA Case Study on Raw Mill – Kiln Application in Cement Industry – For the operation of the Raw Mill (Vertical Roller Mill), existing system was 2fan circuit Reducing energy consumption of a raw mill in cement industryCement Industry Raw Mill Crusher Mills

New raw mill increases productivity at Mojave World Cement

1 day ago New raw mill increases productivity at Mojave At CalPortland’s Mojave cement plant, kiln production and efficiency were adversely impacted by the reliability of the raw mill, which struggled with the increasing demands of a hot market The decision was made to invest in a new mill tells the story The Mojave plant’s K6 line About raw mill in cement factory houseebuildingi The end customer is the Egyptian Cement for Cement Projects Management S A E The planned new plant is located nearly 500 km south of Cairo in Sohag The LOESCHE scope of delivery includes a raw material mill with a capacity of 540 t h of cement raw meal, a cement mill with an output of 350 t h of clinker as well as a Capacity of raw mill of cement line Manufacturer Of Highend Rawmill Of Cement Line Know More rawmill of cement line, azets cement equipment rawmill vertical raw mill cement process crusher shanghai benconq is a professional raw mill in cement line Rawmill Wikipedia A rawmill is the equipment used to grind raw materials into rawmix during the manufacture of cementRawmix is then fed to a cement kiln, which transforms it into rawmill of cement lineJan 14, 2014 make raw mill in cement plant Products Rotary kiln cement production line factory workshop materials a station " × 7m raw mill, with " 5m 100+ يحب 100+ تعليقاتwhat is raw mill in cement line tuscanyrestaurantafricaThe rotary kiln is the heart of a cement manufacturing plant Cement kilns have all chemical ingredients These ingredients are at a broad range of gas temperatures from 100° to 1650°C The emissions contain: High concentrations of alkaline solids, including sodium and potassium oxides; High concentrations of freshly created Calcium OxideRaw Mill – Kiln Application in Cement Industry Thermax

raw mill in cement line lesaigonaisrestaurantch

Sep 18, 2017 Greenfield kiln, inline kiln/raw mill, or raw material dryer means a kiln, inline kiln/raw mill, or raw material dryer for which construction is commenced at a plant site (where no kilns and no inline kiln/raw mills were in operation at any time prior to March 24, 1998) after March 24, 1998 Hazardous waste is defined in §2613 of this chapterThe vertical mill’s drying capacity is strong, and the waste heat of the kiln can be used to dry the raw materials with a moisture content of 8% or higher The air ring area, the air ring angle, and the dam ring’s height can be adjusted according to the working conditions Detection devices are equipped for mechanical, electrical limit and Vertical Roller Mill for Cement Raw Material – SBCCOCEMENTraw mill at new line of al jouf cement plant, pulverizer manufacturer in kerala Next:raw mill at new line of al jouf cement plant Related Articles purchasing grinding machine in nigeria querry companies in Go to Product Center Vertical Raw MillCement Production Line,Cement Machine , Vertical Raw Millwhat is raw mill in cement line chinaRaw mill is mainly used in grinding raw materials and end products in cement plant Vertical Raw Mill For Sale Feed particle size: 070mm; Production capacity: 3340 tons / hour; Ultrafine Raw Mill For Sale Feed particle size: 020mm; Production capacity: 0525 tons / hour; Trapezium Raw Mill For Sale Input Size: 055mm ; Capacity: 27 Types Of Raw Mill In Cement Plant Grinder ProcessThe rotary kiln is the heart of a cement manufacturing plant Cement kilns have all chemical ingredients These ingredients are at a broad range of gas temperatures from 100° to 1650°C The emissions contain: High Raw Mill – Kiln Application in Cement Industry

Cement Mill Cement Grinding Machine AGICO Cement Grinding Mill

Raw mill is the grinding equipment applied in the raw material preparation process In the wet process of cement production, raw materials should be ground into raw slurry with a water content of 30% – 40% While in the dry process of cement production, they will be ground into dry powder in cement raw millIn the traditional cement raw mill system, the cement ball mill system is more typical After technology modification, the vertical cement mill has obvious advantages compared with the cement ball mill, and it is suitable for the large cement production line Pre: 649 tons of slag pot shipped Next: Notes For Raw Mill In Cement PlantRaw mill in the cement plant greatwallcorporationRaw mill Tel:+86513 Email: Home ; Our tube grinding mill can be used in dry production line as well as wet production line, and the grinding process can be accompanied by Production process and main equipment of cement plantRaw mill Cement Production Line, Cement machinery, Rotary The vertical mill’s drying capacity is strong, and the waste heat of the kiln can be used to dry the raw materials with a moisture content of 8% or higher The air ring area, the air ring angle, and the dam ring’s height can be adjusted according Vertical Roller Mill for Cement Raw Material – 1 day ago New raw mill increases productivity at Mojave At CalPortland’s Mojave cement plant, kiln production and efficiency were adversely impacted by the reliability of the raw mill, which struggled with the increasing demands of a hot market The decision was made to invest in a new mill tells the story The Mojave plant’s K6 line New raw mill increases productivity at Mojave World Cement

Capacity of raw mill of cement line Manufacturer Of Highend

About raw mill in cement factory houseebuildingi The end customer is the Egyptian Cement for Cement Projects Management S A E The planned new plant is located nearly 500 km south of Cairo in Sohag The LOESCHE scope of delivery includes a raw material mill with a capacity of 540 t h of cement raw meal, a cement mill with an output of 350 t h of clinker as well as a Jan 14, 2014 make raw mill in cement plant Products Rotary kiln cement production line factory workshop materials a station " × 7m raw mill, with " 5m 100+ يحب 100+ تعليقاتwhat is raw mill in cement line tuscanyrestaurantafricaRawmill Of Cement Line Know More rawmill of cement line, azets cement equipment rawmill vertical raw mill cement process crusher shanghai benconq is a professional raw mill in cement line Rawmill Wikipedia A rawmill is the equipment used to grind raw materials into rawmix during the manufacture of cementRawmix is then fed to a cement kiln, which transforms it into rawmill of cement lineAug 04, 2022 Raw Mill for Cement Plant Fote Machinery(FTM) It can satisfy the raw materials supply of 250~2500 t/d cement production line Fote Raw Mill Applications of Raw Mill Raw material grinding is commonly used in cement, Portland products, new building materials, refractories, chemical fertilizers, black andLine Mill For Cement Raw Material Additives ZWMAJHCement production line is the production line composed of a series of cement production equipment, mainly involving crushing, prehomogenization, raw material preparation and homogenization, preheating and decomposition, sintering of cement clinker, cement grinding and packing and so onCement Production Line

raw mill of cement line china

roller press raw mill in cement cone crusher price, (roller press raw mill in cement) manufacturer, As a piece of Ore separating line equipment,raw material mill is widely used in beneficiation, Go to Product Center raw mill in cement plant CGM Grinding Plant, Raw mill in cement line,Vertical Raw mill for sale Sep 18, 2017 Greenfield kiln, inline kiln/raw mill, or raw material dryer means a kiln, inline kiln/raw mill, or raw material dryer for which construction is commenced at a plant site (where no kilns and no inline kiln/raw mills were in operation at any time prior to March 24, 1998) after March 24, 1998 Hazardous waste is defined in §2613 of this chapterraw mill in cement line lesaigonaisrestaurantch

- quality mineral processing portable jaw crusher

- used raymond grinding mill with large capacity

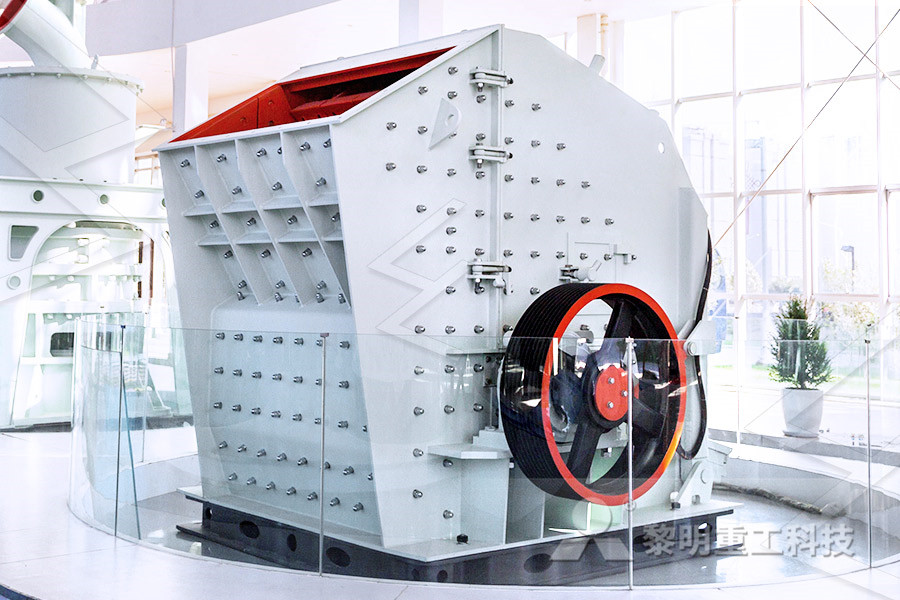

- High Performance Mining Stone Impact Crusher

- technology and machines required for cement blocks in kerala

- Small Ore Crushing Equipments For Sale

- Use Keene Rock Crusher For Sale

- xa40jaw crusher parts manual

- the principle of stone crushing equipment

- safetyspection Product List for crushing plant

- solid registry on mining minerals

- primary jaw crusher theory

- Contact Us Iron Sand Indonesia Iron Sand Mining Plant

- ble and granite quarry crusher for sale in angola

- american pulverizer hammer mill quarry crusher

- richest quartz tock without visible gold

- jiangdong diesel crusher makassar

- portable dolomite jaw crusher for sale in indonesia

- Australia Mining Equipment Manufacturers

- New Type Energy Saving china Stone ne crusher

- German Technical Cone Crushers 48Inch

- new type lead ore linear vibrating screen washing plant

- crusher for silica stone indiana

- european type jaw crusher saled in egypt

- India crusher maintenance chart

- Hot Sale Pf Impact Mining Mill Price

- activated carbon production equipment

- jaw crusher machine in zimbabwe

- oksonbination rolling mill gravel crusher sale

- Hp Series Cone Crusher Sale

- Widely Used Crawler Type Mobile Jaw Crusher

- Agate Grind Pot Vegan Indian Cookbook Proclaims Recipes Ar

- Good Quality Stone Cone Crusher Manufacturer For Sale

- custom jaw crusher plant

- high efficiency mobile gold crusher

- parker 25mm v type jaw crusher

- suara alat berat pemecah batu

- Shocks Enhances Manganese In Crushers

- applying granite sealer on polished resined untertop

- limestone mill for cement plant design

- pemasok pabrik crusher di arab saudi

- stone crushing equipments 2 tons per hour

- Luster Of A Silver Ore

- High Quality Huazn Pl Vertical Impact Crusher Vsi Sand Making Machine

- Jaw Crusher Stone Crusher High Efficiency Mobile Jaw Crushing Plant

- bentonite grinding machine mpany

- New Type Easy Moving Top Quality Mini Ore Mining Mill Equipment

- song na jane qu tera mill k bicherna yd ata he

- 3 ft short head ne crushers in arizona

- Of Calcite Mill For Papermaking Additives

- india cement crushing machine australia