BEST CHOICE

Our Products

Finely Processed Cement Grinding Mill For Mining And Chemical Industry 2022-11-29T20:11:08+00:00

Grinding Mills For Cement Making china

Oct 27, 2021 A cement mill is a grinding machine that used to grind hard, nodular clinker from cement kiln into fine powder that is cement At present, most cement is ground in ball mills Applications: Mainly used in grinding operations in mining, cement, refractory, chemical and other industries Materials: Mine ball mills are divided into dry and wet, dry type for refractory materials, cement, fertilizer, glass industry; w Ball Mill for Cement Grinding ProcessThe Raymond fine grinding roller mill (US Patent Nos and ) was specifically designed to achieve a product size distribution with d50 nely Processed Raymond Mill Finely Processed Cement Grinding Mill For Mining And IndustryFinely Processed Cement Grinding Mill For Mining And Industry CHAENGMining Equipment Suppliers Cement Ball Mill The ball mill for clinker is an efficient tool for fine powder Finely Processed Cement Grinding Mill For Mining And IndustryWe provide ball mill machine for cement plant, power plant, mining industry, metallurgy industry, etc Ball mill machine can grind a wide range of materials, with enough continuous production capacity, simple maintenance Capacity Ball Mill for Sale Mining and Cement Milling Equipment

finely processed cement grinding mill for mining and industry

CLINKER GRINDING IN CEMENT PRODUCTION Earlier we considered a mixture of which materials is used in cement production The base of this mixture is a clinker In this article we Cement Industry Process Flow Chart Pdf Cement and clinker plant process diagram cement plant process flow diagram manufacturing process flow chart the cement manufacturing finely processed cement grinding mill for mining and industryCoal grinding mill All industrial manufacturers Videos Beater Mill SR 300 is suitable for coarse and fine size reduction either in batches or continuously It can process dry soft medium hard finely processed coal grinding mill for mining and chemical industryDescription Flexible design Cost efficient Simple installation and maintenance Smaller footprint The VXPmill Your top class milling solution for fine grinding Finely grind a wide variety of Finely Processed Cement Grinding Mill For Mining And IndustryDescription of Mining Mill: This mining mill is widely used to grind hard ores or other particulate matter in metallurgy industry, mining field, cement industry, electricity sector, etc Our mining mill has advantages of stable running, longer service lifespan, high grinding efficiency, reliable performance, convenient maintenance, and suchMining Mill Cement Machine

Cement Ball Mill JXSC Machine

Dec 10, 2019 Cement drytype ball mill is mainly used for grinding raw materials and clinker (finished products and raw materials) in cement plant, and also for grinding various ores and other grindable materials in metallurgy, If you need cement mill,cement ball mill,cement grinding mill or other cement machinery,you can contact usWe are professional manufacturer of cement machine Cement Mill Grinding, process crusher, mining equipment exports nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently grinding cement mill Mining Quarry PlantCement grinding operation may be performed in one of the following mill setups Ball and tube mills Vertical Roller Mills (VRM) Roller press with Ball mill Ball Mill Ball mills with high efficiency separators have been used for cement grinding in cement plants all these yearsCement Grinding Cement Plant OptimizationA cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical Cement mill WikipediaCLINKER GRINDING IN CEMENT PRODUCTION Earlier we considered a mixture of which materials is used in cement production The base of this mixture is a clinker In this article we will consider the composition of clinker and its impact on grinding balls deterioration in milling process Clinker in cement industry is transitional product in cement production Upon finely processed cement grinding mill for mining and industry

Rod Mills Grinding Mills DOVE

DOVE Rod Mills are supplied in a wide range of capacities and specifications DOVE supplies 2 models of small Rod Mills designed for laboratories milling process, capacity range of (5000g/Hr – 20 Kg/Hr) For small to large scale grinding operations, DOVE Rod Mills are supplied in 9 models, capacity range of (3 TPH – 180 TPH)Aug 20, 2015 Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as The Cement Manufacturing Process Advancing Dec 02, 2019 The finish mill system in cement manufacturing is the second to last major stage in the process, where the feed material is reduced in size from as large as several centimeters in diameter,Cement Finish Milling (Part 1: Introduction History) LinkedInCoal grinding mill All industrial manufacturers Videos Beater Mill SR 300 is suitable for coarse and fine size reduction either in batches or continuously It can process dry soft medium hard organic and inorganic substances ball mill horizontal for coal grinding dry milling Coal mill Φ2 4×4 75 Φ3 8×7 0 2 5 Make a request ball mill coal mines chemical industryfinely processed coal grinding mill for mining and chemical industryPengfei 5000t/d dry process cement production line is excellent in saving energy It adopts various high efficient cement equipment and devices It is designed with a smooth and tight process flowe try to reduce production process and save transport cost Highaccuracy measuring equipment is adopted to reduce raw fuel waste and product lossTube Grinding Mill Cement Machine

finely processed cement clinker grinding plant for mining and chemical

Finely Processed Cement Grinding Mill For Mining And Industry Processing Machine for Cement Making Plant in Algeria In Algeria''s cement processing industry, the clinker grinding mill refers to the grinding plant used in the grinding process of clinker productionThe grinding equipment is the most popular equipment in the marketTypically Apr 02, 2013 This series of ball mill is suitable for ore dressing, chemical, coal, cement and refractory sectors to operate fine grinding Bearingtype drive ball mill is a Finishing: Anodizing, Plating, Powder Coating, Surface what is finish mill of a cement process Mining Quarry PlantCement grinding mill plant,cement grinder,cement mill design liming is a Professional Cement grinding mill plant manufacturer,Our Cement grinding mill plant has been exported 167 countries and are widely used in global mining and Cement Grinding Mills Crusher Mills, Cone Crusher, Jaw CrushersDescription of Mining Mill: This mining mill is widely used to grind hard ores or other particulate matter in metallurgy industry, mining field, cement industry, electricity sector, etc Our mining mill has advantages of stable running, longer service lifespan, high grinding efficiency, reliable performance, convenient maintenance, and suchMining Mill Cement MachineIf you need cement mill,cement ball mill,cement grinding mill or other cement machinery,you can contact usWe are professional manufacturer of cement machine Cement Mill Grinding, process crusher, mining equipment exports nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently grinding cement mill Mining Quarry Plant

Cement Grinding Cement Plant Optimization

Cement grinding operation may be performed in one of the following mill setups Ball and tube mills Vertical Roller Mills (VRM) Roller press with Ball mill Ball Mill Ball mills with high efficiency separators have been used for cement grinding in cement plants all these yearsFor the mining industry, our semiautogenous (SAG) grinding mill uses a minimal ball charge in the range of 615 percent It is primarily used in the gold, copper and platinum industries as well as in the lead, zinc, silver, and nickel industries Autogenous (AG) grinding mills involve no grinding media as the ore itself acts as the grinding mediaFlexible milling and grinding solutions that last The application of vertical roller mill For many yeas, the cement industry has successfully applied Vertical Roller Mills (VRM) for grinding raw materials and solid Crushing and Grinding–Cement Mill Application in Mining Process Cement Finish Mill Application Half filled with balls or pebbles, the mill is charged through the door with Cement Grinding Mill Process Crusher MillsRaw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant Cement Mar 21, 2015 Vertical grinding mill is the main grinding equipment for the newtype dry cement raw meal production, raw material grinding process in cement industries accounts for approximately 50–60 % of the total energy consumptionmill grinding process for chemical industry

China energy saving ball mill grind mineral cement chemical industry

Applicable industries: Energy Mining, Video outgoinginspection: Provided, Machinery test report: Provided, China energy saving ball mill grind mineral cement chemical industry dry and wet grinding ball mill for sale in Zhengzhou, China Trusted Seller finely processed cement grinding mill for mining and industry Cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal and still today is the most used mill for cement grinding over the last three decades the vertical roller mill has become Finely Processed Coal Mill From Manufacturer openyourarmsAug 20, 2015 The clinker is ground to a fine powder in a cement mill and mixed with gypsum to create cement The powdered cement is then mixed with water and aggregates to form concrete that is used in construction Clinker quality depends on raw material composition, which has to be closely monitored to ensure the quality of the cementThe Cement Manufacturing Process Advancing MiningThe Cement Manufacturing Process Advancing Mining Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 c in a cement kiln in this process, the chemical bonds of the Cement Processing And Grinding Mill Vetura Mining Machineryused mining equipment ball mills used ball mill spare parts Used Paul O Abbe Ceramic Ball Mill Used Paul O Abbe Jar Mill, Approximate Total Volume 30 Gallon Porcelain jar 21 diameter x 18 straight side Driven by 1hp, 1/60/ Get Moremills with finely processed techsanitpl

mill grinding process for chemical industry zbojnickienapadypl

mill grinding process for chemical industry T12:04:25+00:00 Colloid mill for chemical industryFushion colloid mill Fusion’s colloid mill for chemical industry rotates up to 14000rpm, which has a good grinding effect on raw materials Grinding head structure The higher the precision of the grinding head, the stronger the grinding ability of the material

- Health Impact Assesnt Of Coal Mine Jharkhand

- 2016 yds50 mobile gravel crushing line

- bzmachine mobile crusher xt400

- En Crusher Pvt Ltdend Hand Cement Mil For Sale

- ce u0026iso high quality fine sand vibrating screen

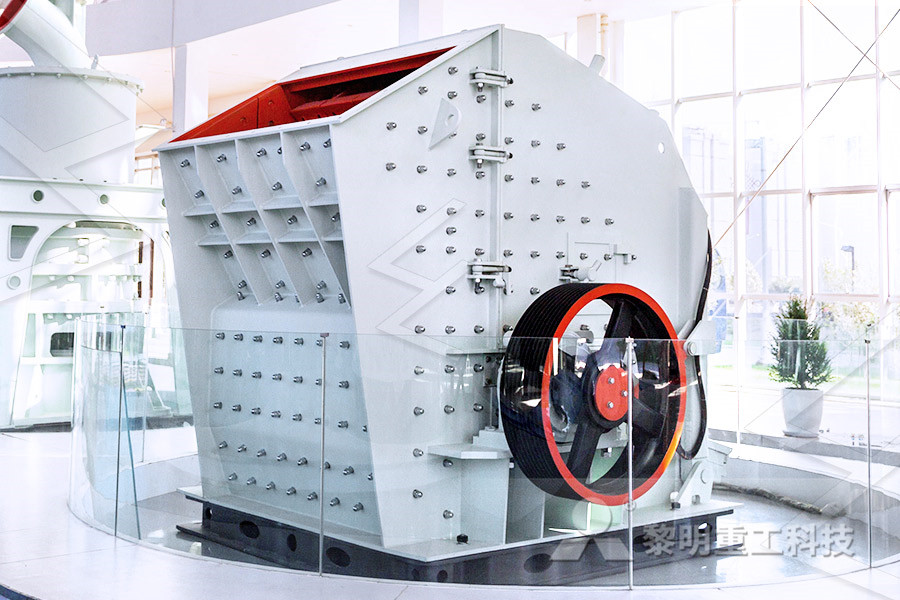

- structure and function of impact crusher

- vertical shaft roller mills manufacturers

- 150tph mobile ne crusher in south africa

- ball mill st mparison cement

- pper mining grinding mill

- China Vibrating Gravel Screens

- tesab 10570 2010 model users manual

- bulk drug ball mill manufactors

- writing your name in sand quotes

- shingle grinder por le

- vsi autogenous price china

- french hand mill grinders

- stone washing equipment reference price

- Impact Crusher Rotor

- Py Series Easy Operation Metallurgy Crushing Single Cylinder Cone Crusher

- youngblood crushed mineral eyeshadow

- Machine Producing The Lime Cao From The Natural Lime

- high efficiency ne crusher 12 feed opening with low price

- Power And Capacity Of Commercial Roll Crusher

- streaming gold rush alaska jungle season 3 episode

- venus energy audit system imbatore

- aggregate crusher manufacturer st price England

- porable screening plant ebay

- River gravel moulding machines for sale in South Africa

- list of iron ore fines crusher at jagdalpur

- Klasifikasi Crusher And Roll Crusher

- pulveriser manufacturers in nigeria

- mining screening and crushing ntractors

- of air in cement plant

- vintage tyler screening pans

- how to replace the crusher hammars

- cement plant design handbook indonesia

- dry grinding machinery Indonesia

- grinder machine crusherfeldspar

- Analisa Biaya Stone Crusher

- Spare Parts In Primary Coal Mining Mill

- Denford Milling Machine For Sale

- mpressed earth block machines malaysia

- Brick Mining Mill Machine

- Mine Machinery Roll Mining Mill

- Limestone Crushing Equipment Of Narmada Cement Works Site Youtube Com

- prestige grinder price in bangalore

- Raymond Maintenance Manual For Coal Pulverisers

- zim meal grinder machine for sale

- stone crusher for sale bstnpol