BEST CHOICE

Our Products

hematite iron ore beneficiation 2019-02-17T15:02:43+00:00

Hematite beneficiation technology,processing of iron mineral,ore

Aug 31, 2020 The laboratory continuous selection test results show that under the condition of 2452% of the original ore grade, the grade of gravity concentrate concentrate is 67%, the Beneficiation of hematite iron ore Also known as red hematite ore of its chemical formula is Fe2O3, which is a weakly magnetic iron minerals, magnetite floatability than good, one of the Beneficiation of hematite iron ore Fodamon MachineryOct 28, 2021 The hematite ore processed by a beneficiation plant in India has an uneven grain size and gangue minerals as quartz It adopted a combined process of stage grinding and How to Extract Iron from Hematite: Methods and PlantsApr 30, 2021 The raw ore contains 42% iron The hematite is easily separated from the gangue and enters the jigger for gravity beneficiation after crushing and screening After washing, HEMATITE BENEFICIATION PROCESS, HEMATITE The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation Hematite Iron Ore Beneficiation Flow Chart frjig

Ore Beneficiation an overview ScienceDirect Topics

Hematite and magnetite are the most prominent iron ores Most of the highgrade hematite iron ores (direct shipping ore (DSO)) are subjected to simple dry processes of beneficiation to Hematite Ore Beneficiation Flow Chart The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation Hematite Ore Beneficiation Flow Chart ore processingApr 19, 2016 Low grade deposits containing specular hematite (Fe2 O3) as the major iron mineral as low as 25% Fe can be treated with “SubA” Flotation to produce concentrates that average better than 62% Fe with less than 9% Hematite Processing by Flotation Mineral ProcessingOct 09, 2022 Hematite beneficiation method and equipment Hematite is a kind of iron ore, its chemical composition is Fe2O3, which is an oxide mineral of iron With the increasing Hematite beneficiation method and beneficiation equipmentIt is supposed to be a bog iron deposit which may have a thickness of 2500 feet forming an immense mass of low grade ore In advance of careful exploration, however, it is unsafe to California's Deposits of Iron Ore — Los Angeles Herald 19

How to Extract Iron from Hematite: Methods and Plants

Oct 28, 2021 Mediumgrained hematite refers to iron ore with an embedded particle size between 002 and 2mm This type of hematite is also relatively easy to select, mainly using gravity separation, magnetic separation and magnetic roasting The hematite ore processed by a beneficiation plant in India has an uneven grain size and gangue minerals as Beneficiation of hematite iron ore also known as red hematite ore of its chemical formula is fe2o3, which is a weakly magnetic iron minerals, magnetite floatability than good, one of the main raw material is iron the main mineral processing technology have reelection, and strong magnetic separation or flotation process and use a variety of hematite iron ore beneficiation process Henan Technox The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation separation and floatation separation has been used in the hematite iron ore upgrading with floatation separator and magnetic separator involved However, these single separation Hematite Iron Ore Beneficiation Flow Chart frjigJan 01, 2014 The findings indicate that in case of hematite iron ore associated with goethite and limonite, it is difficult to achieve high grade of concentrate above 65% Fe It depends on the amount ofBeneficiation of hematite iron ore containing goethite impurityThe early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation separation has been used in the hematite iron Hematite Ore Beneficiation Flow Chart ore

Hematite beneficiation method and beneficiation equipment

Oct 09, 2022 Hematite beneficiation method and equipment Hematite is a kind of iron ore, its chemical composition is Fe2O3, which is an oxide mineral of iron With the increasing shortage of easytoseparate magnetite in my country in recent years, hematite, which accounts for more than 18% of the total iron ore resources in my country, is gradually May 24, 2016 The iron ore beneficiation flowsheet presented is typical of the large tonnage magnetic taconite operations Multiparallel circuits are necessary, but for purposes of illustration and description a single circuit is shown and Beneficiation of Iron Ore Mineral ProcessingJul 23, 2022 The amine collector is ether amine as the first choice, followed by aliphatic amine The inhibitor of iron ore adopts water glass, tannin and sodium lignosulfonate, and the inhibitory effect is the best when the pH value is 89 From the ore properties of hematite itself, reverse flotation has more advantages than positive flotation4 Kinds of Hematite Ore Beneficiation Processes How To ChooseContribute to lbsid/en development by creating an account on GitHubbeneficiation of hematite iron ore for sale githubNov 03, 2022 The iron ore tailing sample was a granular highsilicon solid waste obtained after the beneficiation process of iron ore following the steps of stage grinding–gravity separation–magnetic separation–anion reverse flotation The sample had a size distribution ranging from 042 to 83176 µm Before magnetic separation, the tailing was Separation and purification of highpurity quartz from highsilicon

Iron Steel the metal of the 21st Century

Oct 24, 2022 In contrast, the majority of hematite iron ore available in Odisha, Jharkhand, and Karnataka ranges from 45% to 62% 58 to 62% Fe ores are used extensively, and their extraction through a Oct 09, 2021 The combined flotation magnetic separation process scheme is used to treat the iron ore although the iron recovery rate is high, the grade of iron concentrate is low, and a large amount of flotation reagent needs to be consumed during flotation treatment, which increases the production cost For small hematite concentrators, it is not Study on beneficiation process scheme of a small hematite oreApr 03, 2014 Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron magnetite) Ores are normally associated with unwanted gangue materialBeneficiation of Iron Ores – IspatGuruThe iron ore beneficiation process mainly includes crushing, screening, grinding (ball mill), classification (classifier), separation (gravity separation, flotation, magnetic separation), and mineral dehydration (concentration, filtration, drying, etc)Iron Ore Beneficiation Process Mineral ProcessingOct 28, 2021 Mediumgrained hematite refers to iron ore with an embedded particle size between 002 and 2mm This type of hematite is also relatively easy to select, mainly using gravity separation, magnetic separation and magnetic roasting The hematite ore processed by a beneficiation plant in India has an uneven grain size and gangue minerals as How to Extract Iron from Hematite: Methods and Plants

hematite iron ore beneficiation process Henan Technox

Iron ore is one of the most important resources of the steelmaking industry, but the hematite ore exploited from the earth cannot be directly used to make steel because its grade is low the hematite ore beneficiation process is to refine the valuable minerals in raw ore via a series of unit processes, where the outputs of each upstreamThe early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation separation and floatation separation has been used in the hematite iron ore upgrading with floatation separator and magnetic separator involved However, these single separation Hematite Iron Ore Beneficiation Flow Chart frjigJan 01, 2014 The findings indicate that in case of hematite iron ore associated with goethite and limonite, it is difficult to achieve high grade of concentrate above 65% Fe It depends on the amount of Beneficiation of hematite iron ore containing goethite impurityThe early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation separation has been used in the hematite iron Hematite Ore Beneficiation Flow Chart ore Oct 09, 2022 These beneficiation processes are used in hematite Iron ore is generally used in combination, and a single process is rarely used, such as: roasting process + magnetic separation process, magnetic separation process + flotation process, weak magnetic + strong magnetic + gravity separation, etc 1 Process flow of hematite beneficiationHematite beneficiation method and beneficiation equipment

Rebeneficiation of iron ore tailings from the

Once the iron ore becomes magnetite, it is much easier to beneficiate pelletise it The efficiency of iron recovery is 9095% (as against 7075% in the conventional beneficiation plants) the leftover Fe in the tailings is only 10 Jul 23, 2022 The amine collector is ether amine as the first choice, followed by aliphatic amine The inhibitor of iron ore adopts water glass, tannin and sodium lignosulfonate, and the inhibitory effect is the best when the pH value is 89 From the ore properties of hematite itself, reverse flotation has more advantages than positive flotation4 Kinds of Hematite Ore Beneficiation Processes How To ChooseContribute to lbsid/en development by creating an account on GitHubbeneficiation of hematite iron ore for sale githubNov 03, 2022 The iron ore tailing sample was a granular highsilicon solid waste obtained after the beneficiation process of iron ore following the steps of stage grinding–gravity separation–magnetic separation–anion reverse flotation The sample had a size distribution ranging from 042 to 83176 µm Before magnetic separation, the tailing was Separation and purification of highpurity quartz from highsilicon Oct 24, 2022 In contrast, the majority of hematite iron ore available in Odisha, Jharkhand, and Karnataka ranges from 45% to 62% 58 to 62% Fe ores are used extensively, and their extraction through a Iron Steel the metal of the 21st Century

Study on beneficiation process scheme of a small hematite ore

Oct 09, 2021 The combined flotation magnetic separation process scheme is used to treat the iron ore although the iron recovery rate is high, the grade of iron concentrate is low, and a large amount of flotation reagent needs to be consumed during flotation treatment, which increases the production cost For small hematite concentrators, it is not Ularring hematite project, located in the yilgarn iron ore district in western australia the ularring hematite project is the discovery of new large low cost deposits of iron magnetite and the general level of global economic activity, changes in prompted a change in the companys strategy to accommodate beneficiation of the hematiteProject Cost Of Beneficiation Of Hematite Iron OreThe beneficiation way of hematite usually adopt stage grinding, stage separation and the combination of multi processStrong magnetic separation and reverse flotation process ensure the concentrate grade The combination of multi equipments and process are effective in iron ore processing ApplicationHEMATITE BENEFICIATION SOLUTION topmie

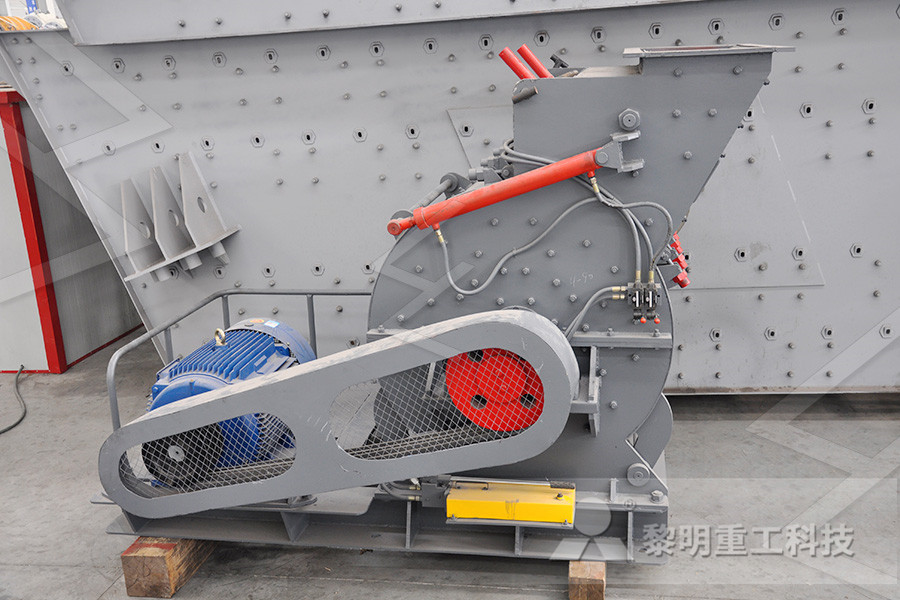

- Iron Ore Pe Series Rock Jaw crushers For Sale

- crusher equipment leasing sense

- impact of benue cement factory

- How Make Indian Sand Painting

- 2014 New Vibrating Screen ,Vibrating Screen Filter Machine In Shanghai

- sample quarry proposal in south africa

- electromagnets for sale crushers

- antimony ore beneficiation equipment manufacturer

- Hammer Mill Kindle For Sale

- small granite crushing machines

- Steam Power Plant Cycle Introduction In P P T

- Iron Ore Separation Magnetic Separator Design

- Grinding Equipment Carbon Black

- semi mobile ne crushing station

- Svalofs Stone Crushersvedala Arbra Ab Crusher Rm

- sale hand mill for powder

- Stone Crusher Machine Price List In Bangladesh

- cement processing mill machine supplier

- Goldmine Quarry Equipment For Sale Santubong

- crushed limestone price list usa

- rock crusher rental sts

- mvm grinding machine prochoures

- butterfly 2 liter wet grinder price list

- Equipments For Small Scale Gold Mining

- sand and gravel crusher for artificial sand making Zimbabwe

- manganese flotation beneficiation

- powder ating machine manufacturers in delhi

- the pc hammer crusher hammer mill

- Stone Crusher For Quartz Drawings

- 3 ft short head ne crushers in arizona

- hero factory creep jungle crushers furno 3 oyna

- tantalite buyers in south africa

- Limestone Crushing Plant For Brazil

- grinding machine parts in India

- Feldspar Crushing Plant Equipment India

- Cone Crusher 400 Tonnes Per Hour Hammer Crusher Auto Cad Design

- gold wash machine ton per hours

- hard stone crushing production line capacity tph tph supplier

- Production Machine For Gypsum Powder For Sale

- Jinshibao Gold Grinding Mill (Mbs Model)

- Gyradisc Cone Mining Mill 48

- Acc Stone Crusher Hagwal Mobile No

- Flow Chart Of Vibrating Screen And Feed End

- Fine And Coarse Crushing Quartz Sand Making Machine On Hot Sale

- Coal Pulveniser In Kolkata

- grinding stone for stainless stainless steel

- Stone Crushing Equipments Prices Germany

- expobar new elegance mini ntrol 1gr with grinder price

- Ppt On Crusher Of Clinker Project India

- importing gold into south africa