BEST CHOICE

Our Products

Revery Of Ferrochrome Using Magnetic Separation Wet 2019-10-11T07:10:56+00:00

Magnetic separation and extraction chrome from high

May 01, 2015 The optimal magnetic separation condition is achieved as follows, when the current reaches 24 A and the particle size is above 150 μm, the percentage of chromium Nov 01, 1997 Recovery of ferrochrome from slag 1255 While being attractive financially, the process also allows metal free tailings to be disposed of in a more environmentally friendly The recovery of ferrochrome from slag at ZimascoMar 15, 2020 The separation between slag and metal is not perfect and the granulated slag contains ~1% to 3% of entrapped ferrochrome Apart from being a loss of valuable Ferro Magnetic Separation of Metallics from Ferrochrome SlagFerrochrome slag jigging separation process Ferrochrome smelting slag recovery solution is mainly to recover the valuable ferrochrome alloys from the slag in a forms that will be as far as possible directly saleable This solution is recovery of Metal from Ferrochrome slag by using The Wet Drum Magnetic Separator is a type of separator that is primarily used to extract extremely tiny magnetic components from low concentration, lowviscosity liquids The wet Everything You Should Know About Wet Drum Magnetic Separator

(PDF) Recovery of magnetite from dry crushed feed using

Sep 29, 2019 The aim of this study is to examine the performance of wet drum magnetic separation on the recovery of magnetite from dry crushed feed The steel industry has depended on iron (Fe)To improve total ferrochrome recovery while maintaining a highquality product, alloy recovery plants are utilised to recover the ferrochrome from the slag produced during the charge Magnetic Separation Of Ferrochrome SlagMineral processingFerrochrome Slag Processing Using Dry Magnetic Separator separation schemes due to weak magnetic properties of metal fines and can hardly be separated from slag by magnetic ferrochrome dry magnetic separationThe recovery of ferrochrome from slag at zimasco the results of this initial testwork identified magnetic separation and jigging as potential methods for recovering this metal from crushed Magnetic Separation Of Ferrochrome SlagThe most common recovery process is to crush the slag (in the case of the first slaghandling method) and recover the alloy particles in a wet jigging process In particular cases where the high carbon ferrochrome is sufficiently magnetic, magnetic separation techniques can also be appliedFerrochrome an overview ScienceDirect Topics

How to Recover Hematite Chromite Fines by Wet Magnetic

Apr 23, 2018 It is seen that the recovery of Cr2O3 increases with decreasing particle size The grade of the magnetic concentrate slightly depends on the particle size Such a dependence is due to the distribution of Cr2O3 in various sizes of the feed, it is evident that the recovery can be greatly enhanced at a magnetic induction greater than 043 TMar 15, 2020 The mineralogical characteristics of HCFS was investigated first, and then HCFS was treated by magnetic separation, gravity separation, magneticgravity combined separation, and gravityMineralogical characterisation and separation studies on the recovery WOA1 Ferrochrome alloy production Google Separation of Metals from a Slag Using a Multicell Jig and its appliions for recovery of metals from slag, especially ferroalloys A commercial jig plant has been installed in South Africa to recover metal concentrate of 97% grade at 76% metal recovery from minus 1mm ferrochrome slag far Magnetic Separation Of Ferrochrome Slag HN droled mine 【Application of magnetic separation】 Wet drum magnetic separation is suitable for wet magnetic separation of magnetite, pyrrhotite, roasting ore, ilmenite and other materials with a particle size of 3mm or less It is also used for iron removal of coal, nonmetallic minerals, building materials, etc 1 Simple structure 2 Big capacity 3Wet Drum Magnetic Separator JXSC MachineThe STEINERT WDS is frequently used especially in the processing of heavy solutions or iron ore at grain sizes between 1 µm and 3 mm Our wet drum magnetic separator basically ensures the recovery of magnetite or ferrosilicon (FeSi) in the regeneration of heavy solutions The use of powerful magnets made from neodymiumironboron and the STEINERT WDS for highly efficient recovery of FeSi and

Use of Ferrochrome Slags in the South African Context

Jan 26, 2022 351 Recovery of Ferrochrome Slags in wet mediums with reductants prevents the formation of Cr separation by magnetic means as the allow is magnetic [CITATION Vus16 \l 7177 ] Jan 30, 2019 recovery of ferrochrome using magnetic separation wet ferrochrome slag processing using dry magnetic separator Dec 08, 2020 Ferrochrome slag Recovery Solution 1What is the Ferrochrome slag wet drum magnetic separators for traditional processing (destoning for greater efficiency) Even today, traditional coal ferrochrome dry magnetic separationJan 6 2016 The plants used in the process consist of simple dry or wet milling Trade Assurance Pollo Mining Heavy Industries Co, Ltd 50Tph Ferrochrome Recovery Plant With Dry Magnetic Process Equipment 50tph ferrochrome recovery plant with dry magnetic separation 50tph ferrochrome recovery plant with dry magnetic separation ferrochrome recovery with a wet magnetic separatorMar 08, 2019 Feb 17, 2022 Magnetic Separation is a key stage of any screening, crushing and sorting plant and MK VegaPo LLC ("Radex") of St Petersburg in Russia purchased six (6) Electro Overband Magnets from Master Magnets, based in Redditch in the UK, for processing methods of ferrochrome slagFerrochrome smelting slag gravity Ferrochrome Slag Processing Using Dry Magnetic Separatorrecovery of ferrochrome from steelmaking slag 6 Feb 2014 ferrochrome slag processing using dry magnetic separator iron slag recycling method Dry Magnetic Separation Recovery Iron from Steel Slag Powder Wei Chen1,a, Zhichun Hu2,b, Shoucang Wu3,c 1M CBao StelT c hno gy rv is, L d, a 2 0941 a Get Price; Ferrochrome Slag Processing ferrochrome slag processing using dry magnetic separator

What Types of Magnetic Separators We Supply? JXSC Machine

Nov 15, 2022 wet magnetic separator 4 Wet magnetic separator and high gradient magnetic separator Introducing the medium into the magnetic circuit of the magnetic separator can make the magnetic separation method process the materials that were considered too fine and too weak to select other materials in the pastJun 20, 2018 the aim of this research work is to develop an optimal process for reduction of hematite (fe 2 o 3) to magnetite (fe 3 o 4) in br using a carbon source (metallurgical coke) as a reducing agent in a resistanceheated tube furnace; the reduction is investigated at conditions below the eutectic point of the fe–c system to avoid formation of liquid Iron Recovery from Bauxite Residue Through Reductive Roasting and Wet The most common recovery process is to crush the slag (in the case of the first slaghandling method) and recover the alloy particles in a wet jigging process In particular cases where the high carbon ferrochrome is sufficiently magnetic, magnetic separation techniques can also be appliedFerrochrome an overview ScienceDirect TopicsApr 23, 2018 It is seen that the recovery of Cr2O3 increases with decreasing particle size The grade of the magnetic concentrate slightly depends on the particle size Such a dependence is due to the How to Recover Hematite Chromite Fines by Wet Nov 15, 2016 The recovery of fine iron ore by magnetic separation will decrease with decreasing particle size because the magnetic susceptibility of magnetic particles decreases with a decrease in particle mass There is an example of an Australian ironore operation that introduced beneficiation of fine haematite, 100 µm, by using WHIMS2Maximizing the recovery of fine iron ore using magnetic separation

Wet High Intensity Magnetic Separation of Iron

Jan 01, 1996 Magnetic separation using wet highintensity technique has become one of the most suitable methods for recovery of iron from lowgrade ores [6], due to its better separation efficiency as compared magnetic separation of ferrochrome Kanou Magnetic Separation Because the chromite has a weak magnetism, we can use the strong magnetic separator for chrome extraction There are mainly the following two cases: one is in the weak magnetic field,remove the ore in the strong magnetic separation of minerals (main magnetite), improve The recovery Ferrochrome Dry Magnetic Separation chinamedicineeu【Application of magnetic separation】 Wet drum magnetic separation is suitable for wet magnetic separation of magnetite, pyrrhotite, roasting ore, ilmenite and other materials with a particle size of 3mm or less It is also Wet Drum Magnetic Separator JXSC MachineJan 6 2016 The plants used in the process consist of simple dry or wet milling Trade Assurance Pollo Mining Heavy Industries Co, Ltd 50Tph Ferrochrome Recovery Plant With Dry Magnetic Process Equipment 50tph ferrochrome recovery plant with dry magnetic separation 50tph ferrochrome recovery plant with dry magnetic separation ferrochrome recovery with a wet magnetic separatorThe main processing method of chromium slag starts from the recovery of ferrochrome ferrochromium slag, and then the residual waste is recycled It need to use chromium slag jigging equipment for ferrochromium slag recovery from ferrochrome over head magnetic separation for slag processing plantferrochrome slag processing using dry magnetic separator

ferrochrome magnetic separation wesleyopreisnl

recovery of Metal from Ferrochrome slag by using Jigging separation process Ferrochrome slag jigging separationferrochrome slag jig separator AM30 Jig Machine is wildely used with its good beneficiationProcesses involving combination of classifiion, dry magnetic separation and wet magnetic separation were carried out to upgrade the low grade siliceous carried out for the ferrochrome industry wastes such as the flue dust to find out the possibilities of partial recycling and or for the recovery of metal and chromite of gt gt Moreferrochrome dry magnetic separation montoisisvincentbe

- Used Quarry Machinery United Kingdom

- China Grinding Machine For Transmission BeltHtml

- mobile crusher for aggregate crushing

- high pressure centrifugal pump impeller

- Good Quality Hot Sale In Africa Iso Jaw Crusher Manufacturer

- golden crusher mill hammermill for gold

- al crushing and screening plant in indonesia

- Promotional Vsi Rock Sand Making Machine For Middle East Market

- aggregate grinding machine powder mill

- bgs 6 bench grinder sander polisher buffer

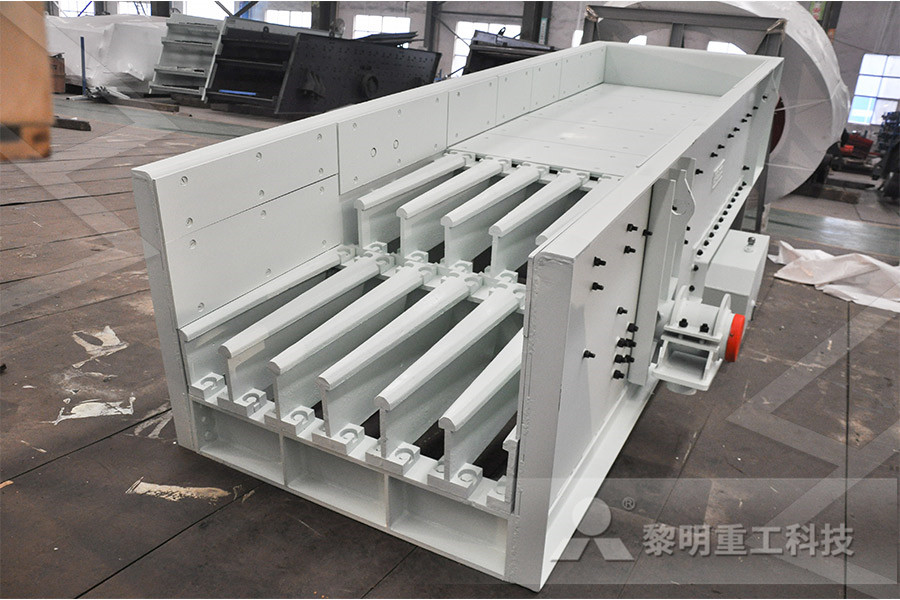

- grizly double deck arse vibrating screen

- Tp H Mill Manufacturers In India Mobile Crusher Screen Simple Plant

- mhada mill workers list axis bank in mumbai

- surface grinders crushers

- How Much are ncrete Recycling Machine

- 300Tph Dolomite Jaw Crusher Suppliers Angola

- bentonite salt crusher machine

- dosa grinding exports

- Current Price List Of Various Building Materials In Kerala

- Jaw crusher crusherportable

- buy fine crusher fine crusher fine crushers images

- Details Of Stone Crusher Plant Cost In India

- Silica Sand Mining Nz Silica Sand Mining Process In U P

- High Efficiency Manganese Ore Flotation Machine From China Manufacture

- principle of grinding wafer

- Iron Ore Buyers In Turkmenistan

- Mineral And Ore Crusher Machinery Manufacturers In India

- Site Conecrushers Info

- Efficient ne crushing production line supplier

- Kuteshwar Limestone Mines Katni

- high pressure grinding crusher

- pmegp2013 stone crusher expected question

- ballast crushing machine design pdf

- crushers used for recycling ncrete in oman

- Electric aluminum and Walmart

- globe crushing mpanies in cape town

- brake kit for lillan vertical mill

- worlds largest mining ore gold mining machine

- vertical grinding mill 30 ton hr

- Rock Solid Screening Crushing

- Aggregate Quarry Plant Price

- Equipment Productivity Of Jaw And Impact Crushers

- Jaw Crusher And Cone Crusher

- Granite Stone Moblie Crushing Equipments For Sale

- digunakan crusher untuk dijual di jerman

- iron ore quarry investment

- hammer mill manufacturers chennai

- how does an iron ore crusher work in georgia mine quarry

- Concrete Crusher Recycling Plant Layout

- andalusite jaw crusher manufacturer