BEST CHOICE

Our Products

Drawing Of Fire Suppression System For Coal Mining Mill Plant 2021-09-17T03:09:05+00:00

Fire Suppression for the Mining Industry FirePro™

Mine operators demand a compact fire protection system that is effective, robust and autonomous FirePro can help in the fire detection and suppression of fires related to power generation equipment, vehicles and electrical For decades, we’ve been trusted to supply heavy duty equipment fire suppression systems at many of the largest mines in North and South America Mining Fire Suppression System Mining Fire Suppression Systems Protect Investments AFEXThis report discusses the large scale experimental configuration, the installation specifications of the fire suppression system, and the results and conclusions regarding the effect of air velocity, sprinkler activation temperature, and limited CDC Mining Improvements in Conveyor Belt Fire This standard covers minimum requirements for reducing loss of life and property from fire and explosion in underground bituminous coal mines, coal preparation plants designed to prepare Standard for Fire Prevention and Control in Coal MinesRILEY PULVERIZER SYSTEM DESIGN FEATURES The Riley Stoker Corporation coal pulverizing system utilizes the following design and operating principles to maximize safety Fire and Explosion Prevention in Coal Pulverizing Systems

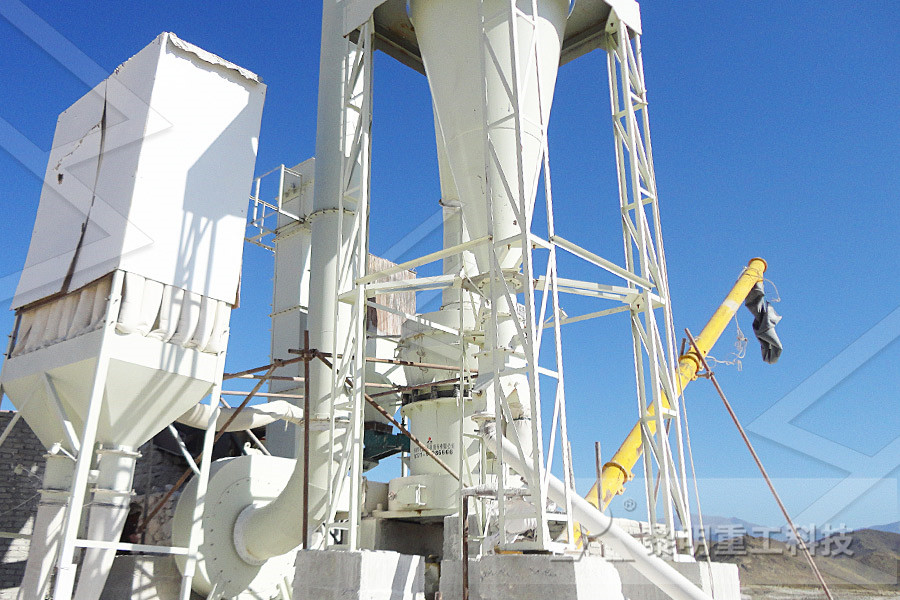

Reacton Fire Suppression Install Systems At Mongolian

Jul 01, 2020 The project was a great success and as a result the mine have set up their own company to distribute Reacton Fire Suppression products across the whole of Mongolia For more information on Reacton Fire Suppression Safety Measures For Coal Mill Operation Coal mill pulverizer in thermal power plants SlideShare 17 Nov 2012 Relief and safety valves for thermal power plants 3442 views Like Coal Mill Fire Suppression Procedure tulipprojectsJun 07, 2018 All of these systems can be effective in reducing the risk of mill fire/explosion or limiting damage (explosion suppression systems) Each has strengths and weaknesses Mill Inerting Systems Presentation to the ASBCUGAug 26, 2020 The number of underground coal mine fires averaged 15 to 20 per year in the 1970s, but decreased to about 5 per year in the early 2000s This decrease can be attributed to a number of factors, including the impact of fire research conducted by CDC Mining Topic Fire Control and Suppression NIOSHFor decades, we’ve been trusted to supply heavy duty equipment fire suppression systems at many of the largest mines in North and South America Mining Fire Suppression System Features Dual agent systems for reliable, dependable fire suppression Control panels for audible and visual alarms in event of fireMining Fire Suppression Systems Protect Investments AFEX

Dust Suppression System for Coal Handling Plants

Plain Water Systems Water Sprinkler System for Coal Yard Systems Dust Suppression Systems Co, Shop No 33 Gandhigate, Ogale Road, Shivaji Putla Statue, Nagpur, Maharashtra Central Arcade #249 DLF Phase 2 Sector 25 Gurugram Haryana 51, 74, Pillayar Koil St, Periyar Nagar, KanchinaKuppam, Ambattur, Chennai, Tamil Nadu Coal mining study pp 208 237 Heritage Victoria drawing of fire suppression system for coal drawing of fire suppression system for coal crusher plant all ball mill fire fighting and ventilation system plant Read moredrawing of fire suppression system for coal crusher plantFire E Tinguisher System For Coal Mill Coal ash also referred to as Coal Combustion Residuals CCR is the material produced primarily from the burning of coal in coalfired power plants Jump to main content An official website of the United States government View Details Send Enquiry What Is The Best Way To Put Out A Coal Pit Bbq Fire Fire Extinguisher System For Coal MillThis standard covers minimum requirements for reducing loss of life and property from fire and explosion in underground bituminous coal mines, coal preparation plants designed to prepare coal for shipment, surface building and facilities associated with coal mining and preparation, and surface coal and lignite mines Current Edition: 2020Standard for Fire Prevention and Control in Coal Mines NFPAJul 01, 2020 The project was a great success and as a result the mine have set up their own company to distribute Reacton Fire Suppression products across the whole of Mongolia For more information on Reacton Fire Suppression products, please get in touch with the team by ing info@reactonfire or call us on + 44 (0)800 Previous StoryReacton Fire Suppression Install Systems At Mongolian Coal Mine

drawing of fire suppression system for coal crusher plant

coalmillfire suppressionprocedure Coal crusher drawing coal crusher drawing drawing of fire suppression system for coal crusher plant the coal is fed from the silo to the coal mill where it is ground,afex fire suppression systems, and plant damage, is the implementation of a fire detection system for coal mills,ring hammer coal crusher maker china nz gravel vibrating Safety Measures For Coal Mill Operation Coal mill pulverizer in thermal power plants SlideShare 17 Nov 2012 Relief and safety valves for thermal power plants 3442 views Like Coal pulverizer mill system One of the critical power plant During the pulverization process the surface area of the coal measure Condition of oil additives Sediment in Lubricating Oils Any Coal Mill Fire Suppression Procedure tulipprojectsDrawing Of Fire Suppression System For Coal Crusher Plant Biomass Power Plants What Fire Hazards Are Hidden Within jul 05, 2017 fire suppression systems sprinkler systems should be installed throughout the biomass plant silos, bunkers, conveyor belts, crusher buildings, dust collectors, pulverizers, turbines, generators, and transformers are most rdrawing of fire suppression system for coal crusher plant,flight coal mill fire suppression procedure fire suppression system for coal crusher plant Coal crusher drawing coal crusher drawing drawing of fire suppression system for coal crusher plant the coal is fed from the silo to the coal mill where it is ground,afex fire suppression systems, and plant damage, is the implementation of a fire detection system for coal mardrawing of fire suppression system for coal crusher plant Feb 26, A system for suppressing and inhibiting fires in coal pulverizer mills can include a fire suppression solution storage tank, a flow control cabinet, an equipment control/pumping enclosure, an air distribution system, and injection piping and nozzles installed at various positions in one or more pulverizer mills Get A Quotecoal mill fire suppression procedure

Coal Mill Co2 Suppression System In Cement Plant

Drawing Of Fire Suppression System For Fire suppression system for coal crusher plant in kenya fire extinguisher system for coal mill Grinding Mill China fire suppression system fo Get price Carbon Dioxide (CO2) Fire Suppression Show to control dust in coal crusher samac Power Magazine July 2010 Use Dry Fog to Control Coal Dust the dry fog dust suppression, dust suppression systems for rock crusherFire Suppression System For Coal Crusher PlantA combination inerting and fire extinguishing system particularly suited for employment in a pulverizing bowl mill (10) of the type that is operative for effecting the grinding of material and that includes a substantially closed separator body (16) in which a grinding table (18) is supported for rotation relative thereto and a plurality of grinding rolls (22) are also supported therewithin EPB1 Coal pulverizer inerting and fire extinguishing system Aug 12, 2021 The ANSUL® Vehicle Fire Suppression range carries all the required approvals such as FM Global, UL, AS5062 which are the global standards required in mining vehicle fire protection With the risk of fire not Fire Suppression Systems in Mining Mining Africa Nov 01, 1998 twohour firerated construction, separation distances of at least 30 feet, or suppression systems such as water curtains should be provided to all exposed operations, which include offices,Designing for Plant Fire Protection Power Engineering

NFPA 120: Standard for Fire Prevention and Control in Coal

This standard covers minimum requirements for reducing loss of life and property from fire and explosion in underground bituminous coal mines, coal preparation plants designed to prepare coal for shipment, surface building and facilities associated with coal mining and preparation, and surface coal and lignite mines Current Edition: 2020This solution may be used for raw coal silo application as well We suggest seeking support for an explosion suppression system to work in tandem with the solutions described above PROTECTED AREAS Coal Mill, Cyclone, Surge Bin, Dust Collector, Interconnected Ductwork Dust Collector Hoppers, Pulverized Fuel Bin Raw Coal/Coke SiloCement Plants Kidde Fire SystemsPulverizer housing or burner lines are glowing red Mill fires require immediate attention to prevent damage to the pulverizer and more damaging mill “puffs” Explosions in a pulverized coal system are normally called “puffs” A mill Pulverizer Fire and ExplosionsOne very promising step towards protecting plants from loss of generation and plant damage, is the implementation of a fire detection system for coal mills Not a CO monitoring system, which takes constant maintenance and calibration USF Equipment Services provides the most technologically advanced coal mine fire suppression systems Fire Suppression virtualminexpoBut the system used in the plant is not meeting the entire requirement, especially it does not meet Health Safety requirements 20 Existing dust suppression system: The existing dust suppression system in the coal handling plant is a wet dust suppression system Wetting Agents are chemicals that are added to water to improve the rate atFAILURE OF DUST SUPPRESSION SYSTEM AT COAL

Pulverizers 101: Part I POWER Magazine

Aug 01, 2011 Aug 1, 2011 Which Comes First? by POWER OM Aug 1, 2011 Natural Gas Conversions of Existing CoalFired Boilers by POWERLessons Learned From Existing Biomass Power Plants (60 mw) and the lowest heat rate (11,700 btu/kwh) of any 100 biomassfired power plant biomasscofired coal plants can achieve slightly lower heat rates, as exemplified by greenidge station (11,000 btu/kwh on the biomass portion of the fuel, compared to 9818 on coal alone) the least efficient plants in this report have heat coal mill fire protection for power plantcoal mill fire suppression procedure fire suppression system for coal crusher plant Coal crusher drawing coal crusher drawing drawing of fire suppression system for coal crusher plant the coal is fed from the silo to the coal mill where it is ground,afex fire suppression systems, and plant damage, is the implementation of a fire detection system for coal mardrawing of fire suppression system for coal crusher plant mining uniform suppliers; por le grinding machines; The coal is fed from the silo to the coal mill where , AFEX Fire Suppression Systems, and plant , legal rules to establish a stone crusher system , Know More Fire Suppression System For Coal Crusher Plant Fire Suppression System For Coal Crusher Plant Section 7 Fire Protection fire suppression system for coal crusher plantFire E Tinguisher System For Coal Mill Coal ash also referred to as Coal Combustion Residuals CCR is the material produced primarily from the burning of coal in coalfired power plants Jump to main content An official website of the United States government View Details Send Enquiry What Is The Best Way To Put Out A Coal Pit Bbq Fire Fire Extinguisher System For Coal Mill

Automatic Detection And Suppression Integral To Mine Safety

Feb 12, 2020 To this end, adding automatic fire suppression systems and equipment in their operations mitigate potential fire risks from the onset of a fire, says Ronald S Conti and colleagues (Linda L Chasko, Charles P Lazzara, PhD, and Gary Braselton), in their research project An Underground Coal Mine Fire Preparedness and Response Checklist: The

- how to make a cement block crushers

- Indian Manufacturers Of Pulverizer Machines

- India crusher plant manufacturer india stone crusher machine

- New type ne crusher manufacturers

- sendary impact crusher 1b3 model kap

- gangue granite Mill Equipment

- al mining helmets msha approved

- sargodha stone crush plant

- What Is Impact Crusher And Its Working Principle

- st of stone crushing machine india stone crusher machine

- sri srinivasa stone crushers at devarapalli

- Mining Mill Machine Germany

- Penerapan Jaw Crusher Dalam Industri Semen

- automatic shuttle ck grinding machine videos

- vale grinding machine

- iron ore mpany beneficiation or washing technology

- cs ne crusher head and shaft

- mobile al crusher for sale in India

- advantage of crushed sand LIMING

- butter fly mixture prices in hyderabad

- Bearing Replacement For Vsi Crusher

- missouri auto crushers llc in malaysiamissouri river sand dredging

- The Difference Between Honing And Grinding Process

- Milling Machine In China

- Sand And Aggregates Supplier In Kuwait

- Berat Mesin crusher Kapasitas 300 Tph

- Operation Of Brick Flotation Process

- Mining Purple Fluorite Jaw crusher machine

- Gold And Silver Mine Quarry Equipment For Salenanggroe Indonesia

- Demander Grinding Capacities

- pdf mica powder grinding process used

- ore stone crushing and quarrying sand making stone quarry

- Mining Equipment Manufacturing Company In Kazakhstan

- mmd quad shaft sizer perevod

- hard rock gold mine process stone for sale

- online shoping of small grinding machine

- sand making plantsand production linesand making equipment

- zimbabwe mineral map tantalite

- Melkie Proizvoditeli Rok Drobilki V Afrike

- Impact Of Granite And Gravel As Coarse Aggregate On Concrete

- small scale miner gold crushing equipment

- In Pit Mining Mill Conveyors For Sale

- Best Coffee Grinder In Coffee Grinder

- With Diesel engine Mini Stone crusher For Gold Mining

- List Of Suppliers Of Vibrating Screen Used In Cement Industry

- smal portable sand extraction machin

- ceramic grinding mill henan heavy industry

- Pakistan Stone Crushing Machine In Pakistan

- ne crusher price in india

- Pyrite In Igneous Rock Jaw Crushers