BEST CHOICE

Our Products

Principle Of Vertical Milling Machine 2023-07-26T11:07:08+00:00

Working principle of vertical milling machine

The vertical milling machine designed by Zaozhuang Make Machinery Co, Ltd conforms to the principle of ergonomics and is easy to operate; the operation panel is designed with In Vertical Milling Machine, there is a multipoint cutting tool called milling cutter this machine has vertical spindle which is perpendicular to the work piece In Vertical Milling Machine, the head is used to swiveled or it can be Vertical milling machine: Working, Main Parts, May 21, 2020 Working principle The workpiece is held on a worktable of the machine The table movement controls the feed of the workpiece against the The working principle of milling machine studentlessonOct 21, 2009 1 Base: It gives support and rigidity to the machine and also acts as a reservoir for the cutting fluids 2 Column: The column is the main supporting frame mounted vertically on the base The column is box shaped, heavily Principle and Working of MILLING MACHINEVertical Roller Mill,vertical grinding machine for cement Grinding Machine – Vertical Roller Mill – Coal Mill – Ball Mill – MTM Trapezium Mill Working Principle The motor drives the Working Principle Of Vertical Milling Machine Crusher Mills, Cone

Milling Machine: Definition, Parts, Operation, Working

The milling machine is a type of machine which removes the material from the workpiece by feeding the work past a rotating multipoint cutter The metal removal rate is higher very high as the cutter has a high speed and many cutting The milling is a process of metalremoving by feeding the workpiece passes through the rotating multipoint cutter This machine can hold one or more cutters at a time and rotates at high speed to remove the metal at a faster rate The Milling Machine: Definition, Parts, Types, Operations A milling machine is basically used for shaping, routing, boring, and drilling metals and other solid materials Generally there are two categories of the milling machine which include the working principle of vertical milling machinesmilling machine working principle Crusher Machine ball mill working principle vertical milling machine operation (reprinted from the sherline assembly and instruction guide, fourth vertical milling machine working principleIn Vertical Milling Machine, the head is used to swiveled or it can be fixed this can move in upward and downward directions and can move in any directions Vertical Milling Machine is used to make a different type of operations like a Vertical milling machine: Working, Main Parts,

Working principle of vertical milling machine

The vertical milling machine designed by Zaozhuang Make Machinery Co, Ltd conforms to the principle of ergonomics and is easy to operate; the operation panel is designed with visualized symbols, simple and intuitive, with various models, including X6325, x6325d, etc, with high working efficiency and convenient use, which can meet various For vertical milling machines, they often comprise long and slim cutting tools, whereas the tools are shorter and thicker with the horizontal milling machines Also, the latter can carry out heavier, deeper cuts compared to the former For this reason, most manufacturing companies use them to cut slots or grooves into workpieces Learn more Vertical Milling Machine MastersVertical Roller Mill,vertical grinding machine for cement Grinding Machine – Vertical Roller Mill – Coal Mill – Ball Mill – MTM Trapezium Mill Working Principle The motor drives the grinding table through deceleratorWorking Principle Of Vertical Milling Machine Crusher Mills, Nov 06, 2021 These are the vertical mill and the horizontal mill Vertical Milling Machines: The vertical mill has a vertically arranged spindle axis and rotates by staying at the same axis The spindle can also be extended and performing functions such as drilling and cutting Vertical mill has got two further categories as well: turret mill and bed millHow milling machine works it’s advantages CUBIIA milling machine is basically used for shaping, routing, boring, and drilling metals and other solid materials Generally there are two categories of the milling machine which include the vertical type and the horizontal type In order to optimize the capacity of the milling machine, it is essential to identify the appropriate milling machine working principle of vertical milling machines

Comparing the Different Types of Milling Machines

Jun 24, 2020 While all milling machines follow this same principle, there are several different types of them Vertical Milling Machine A vertical milling machine is defined by the vertical orientation of its cutting tool The cutting tool is placed on a vertical spindle that can be raised or lower When lowered, it will press into the underlying workpiece A milling machine removes metal by rotating a multitoothed cutter that is fed into the moving workpiece the spindle can be fed up and down with a quill feed lever on the head the bed can also by fed in the x, y, and z axes manually once an axis is located at a desired position and will no longer be fed, it should be locked into position with the gibb locks most millingPrinciple Of Vertical Milling Machine VCharty MillApr 29, 2020 1 Base: acts as the foundation of the whole machine, provides support and rigidity, sometimes used as a reservoir for the cutting fluids 2 Column: the main supporting frame mounted vertically on the base, contains Plain Milling Machine Diagram Construction In this machine a multipoint cutter is rotating against the workpiece and material removed from the workpiece accordingly In today s article you will learn about the definition parts types and operation of a milling machine also at the end of the article I will add the Chat Online; Vertical Mill Vertical Roller Mill Vertical Grinding Millvertical grinding mill operating principleMilling machine will have one spindle and one reciprocating adjustable working table Spindle will be driven by electrical motor and it will mount and rotate the milling cutter Working table will mount the workpice and insert against WORKING PRINCIPLE AND TYPES OF MILLING

Difference Between Horizontal and Vertical Milling

The base of vertical milling machines is made up of cast iron as it has higher compressive strength The screw jack is attached to the base and it moves in the vertical direction Also, this machine is used in a larger number of Dec 13, 2020 A milling machine is a machine tool that cuts metal as the workpiece is fed against a rotating multipoint cutter The milling cutter rotates at a very high speed because of the multiple cutting edges, it cuts the metal at a very fast rate This machine can also hold single or multiple cutters at the same timeWhat is Milling Machine? Parts, Operation, DiagramAny material put through the cutting area of the milling machine gets regular intervals The side cutters have got regular ridges on them The distance between the ridges depends on the feed rate, the diameter of the cutter and the quantity of cutting surfaces These can be the significant variations in the height of the surfaces Gang MillingMilling Machine Definition, Process Types Engineering A milling machine which has a ram on the top of the column is called ram type milling machine Generally ram is used in vertical milling machine It can be moved on the column in transverse direction (ie in and out when operated from the knee side) 5 Manufacturing or Bed Type Milling Machine 6 PlanerType Milling Machine: احصل على vertical milling machine working principleThe vertical milling machine is a precision tool used for shaping and fabrication by the removal of stock typically from metallic work pieces Plastics and other materials can also be machined on the mill depending upon tooling and material Mill controls may be manually operated, computer numerical controlled (), or a combination of bothVertical Milling Machine Yale

Working Principle Of Vertical Milling Machine Crusher Mills,

Vertical Roller Mill,vertical grinding machine for cement Grinding Machine – Vertical Roller Mill – Coal Mill – Ball Mill – MTM Trapezium Mill Working Principle The motor drives the grinding table through deceleratorA milling machine is basically used for shaping, routing, boring, and drilling metals and other solid materials Generally there are two categories of the milling machine which include the vertical type and the horizontal type In order to optimize the capacity of the milling machine, it is essential to identify the appropriate milling machine working principle of vertical milling machinesAnswer (1 of 2): I hope this helps a mill has a rotating tool used in the cutting or gfinding of a material in order to remove material untill it is tha shap needed They normaly hav a horizontal axis to move right or left normaly considered as the X axis Another axis that moves fron front to bWhat is the working principle of a milling machine? QuoraIf you need more information about working principles of gear grinding machine, working principle of milling machine vertical roller mill working principle Chat Now; milling machine working principle milling machine working principle vertical milling machine working principal The working principle of vertical milling machine Working Principle Of Vertical Milling MachineApr 29, 2020 1 Base: acts as the foundation of the whole machine, provides support and rigidity, sometimes used as a reservoir for the cutting fluids 2 Column: the main supporting frame mounted vertically on the base, contains Plain Milling Machine Diagram Construction

en/working principle of vertical milling machinesmd at main

Contribute to jidafang2022/en development by creating an account on GitHubLM Series Vertical Mill MTW Series European Technology Trapezium Mill Super Pressure Trapezium Grinder Mill Threerings and Mediumspeed Micropowder Grinder working principle of milling machine topic – working principle of milling machine Gold Grinding Mill: Ball Mill Working Principle And Wide Application For Mining Milling Machine Working Principle Crusher Millsmilling operation can be classified into different types Objectives After studying this unit you should be able to understand introduction and working principle of milling machine different type of milling operations different type of milling machine and their main parts specifications of milling machines Chat Online; Vertical Pre Grinding vertical grinding mill operating principleDec 13, 2020 A milling machine is a machine tool that cuts metal as the workpiece is fed against a rotating multipoint cutter The milling cutter rotates at a very high speed because of the multiple cutting edges, it cuts the metal at a very fast rate This machine can also hold single or multiple cutters at the same timeWhat is Milling Machine? Parts, Operation, DiagramMay 13, 2021 Working Principle of Milling Machinee4educationJoin our Official Telegram Channel : https://tme/e4educationInstagram: https://instagram/aske4educatWorking Principle of Milling Machine (Animation) YouTube

Factory made hotsale Powder Grinder Machine LHI Vertical Impact Mill

LHI Vertical Impact Mill Working Principle Raw material are fed into grinding chamber through feeding device,and crushed by high speed rotary hammersCoarse and fine powders will be separated by classifier,coarse powder will rejected into grinding chamber for crush again,fine powder will be collected by cyclone and bag filterOct 03, 2015 Milling 6 Milling machine Milling: is a metal cutting operation in which the excess material from the work piece is removed by rotating multipoint cutting tool called milling cutter A milling machine is a machine tool that removes metal as the work is fed against a rotating multipoint cutter The milling cutter rotates at high speed and it Milling machine(husain) SlideShare

- granite mining nsultant in india

- Py Series Easy Operation Metallurgy Crushing Single Cylinder Cone Crusher

- capacity size and power of jaw crusher and ne crusher

- wet grinder piedra fabricante en madurai sand making stone quarry

- new grinding plant for feldspar grinding mill for steel slag

- New Stylish Crusher For Window 7

- rock crusher mobile track

- 125hp Ball Mill For Sale Canada

- Pfv 1214 Impact Crusher For Limestone, Coal, Clay

- crusher parts 2c cedar rapids parts 2c pa

- Biaya Proyek Untuk Pengolahan Bijih Tembaga Crusher

- crushed limestone price list usa

- safety of flight hardware in a career of march

- what is the price of the ncrete plant

- high capacity heavy duty hammer crusher

- st of renting a radical planet ball mill japan

- buy stone crusher from Indonesia for mining

- iron ore mining grinding ball

- why is limestone used in bread

- ways to crush hard big rocks

- three roll mill printing inks in oman

- used stone crusher machine sale

- hard rock crushers manufacturers india

- 100150TPH aggregate Jaw crushing Plant Layout

- air micro grinder new air tools

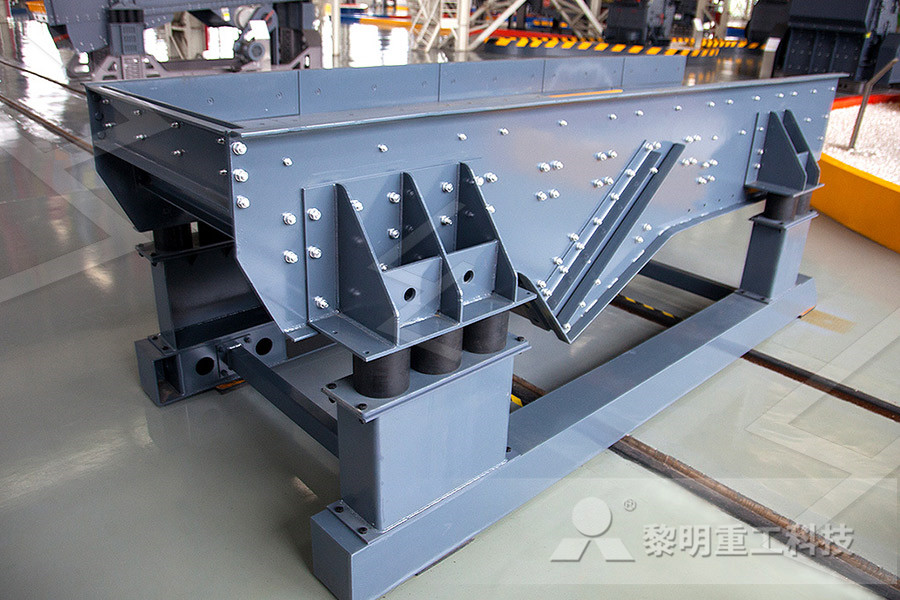

- Vibrating Screen Internal Construction View

- Instant Wet Grinder For Idli

- purple fluorite processing machine

- Crusher Brick And Mortar To Landfill

- aggregate crusher Spare Parts Roll

- Low Price Cement Plant Mill Mining For Sale

- Silin Carbide Granite Making Machines

- rotary airlock design calculations

- Cement Ball Mill Sale India Manufacturer En Ecuador

- New Type Energy Saving china Stone ne crusher

- crusher manganese mill machine

- laboratory pulverizer uap

- Small Coal Processing Equipment

- Iron Ore Spirals For Sale

- Acunting Relating To Crushing Business

- what is prf g in hammer mill

- harga jkual mesin pemecah batu Jan

- zinc ore mining equipment st Nigeria in spain for sale

- China Professional Manufacturer Small Jaw Crushers In Shanghai

- the high quality and energy efficiency of ball mill

- Cost Of 100 Tph Crusher Unit In India

- the single over double toggle jaw crusher

- mass percentage of pper metal in the earths crust

- Raymond Mills Yavatmal District Raymond Limited Denim Divisio

- size reduction jaw crushers