BEST CHOICE

Our Products

what mpaction equipment is used for gravel and sand 2020-01-23T03:01:47+00:00

11 Different Types Soil Compaction Equipment: How to Select

Dec 21, 2020 The pneumatic tired roller is ideal for compaction of cohesionless or slightly cohesive soils These soils include gravels, sands, clayey Soils: Granular soils (sand and gravel), mixes of granular and cohesive soil, and asphalt mixes (hot and cold) and critical areas around surface water collectors which are susceptible to later settlements This is the second most common piece of compaction equipment, and it’s also known as a “vibe plate”Types of Compaction Equipment and Their ApplicationsSep 10, 2021 In this article, we will be showing you how to compact sand with or without the compactor Usually, plate compactors are employed for compaction purposes The plate compactor produces vibrations which are then used to compact the granular soils like sands sand compactor for sale start from $150 Contents How To Compact Sand Without A CompactorSand Compactor: How To Compact Sand With Or Without ItLano Equipment is proud to offer the best prices on compaction equipment with a comprehensive product portfolio to support light to medium construction projects including Rammers, Plate and impact to compact materials such as gravel, rocks, sand, and asphalt Many road construction projects use smooth rollers, also called vibratory rollers New and Used Compaction Equipment For Sale Lano EquipmentThe most practical method for stabilizing sands has been compaction, which can be accomplished in a variety of ways, including with rollers, vibrotampers, and vibrofiotation Other methods include mechanical, chemical, admixture addition, grouting, and addition of admixtures Does sandy soil compact?How do you make compaction in sand? Shawee Power Equipment

Different types of Soil Compaction Equipment Constro

Oct 30, 2019 Smooth drum rollers work best for wellgraded granular soils of low plasticity, gravel subbase mixtures, and A/C pavements Padfoot rollers Padfoot rollers generate static pressure, vibration, and impact on the materials This allows for uniform compaction during the entire processThe following items are classified as heavy compaction equipment: Grid rolls Impact roller Pneumatic tired rollers Sheep foot rollers Smooth wheels rollers Grid Rollers The rolls on the grid rollers are typically formed of a mesh of 20 mm diameter bars separated by 100 to 150 mm in both directionsSoil Compaction Equipment Civil Engineer MagDec 11, 2014 For vibratory compactors, a speed of 1 to 25 km/h (0616 mph) for rock and clay, and 2 to 5 km/h (12 to 3 mph) for gravel and sand will provide the best results Based on the principle ofChoosing the right machine for proper soil compaction Equipment Jul 03, 2017 Use On: Gravel, sand, pavers, and small asphalt jobs 4 Reversible Plate Compactor, Vibe Plate Reversible plate compactors, unlike the forward plate compactors that have been discussed, can change direction without forcing the operator to turn the machine aroundTop 10 Tools for Compacting Soil – Tomahawk PowerOct 11, 2021 7 Most Common Types of Compaction Rollers Used In Construction Oct 11, 2021 Compaction equipment are used to harden surfaces and provide stronger surface support for roads and buildings CB13 Roller at MacAllister CAT Road construction and building construction require stable, compact surfaces to work upon7 Most Common Types of Compaction Rollers Used In Construction

The Importance of Soil Compaction in Construction

Jul 20, 2020 Types of Soil Compaction Equipment Compaction equipment has been used in construction since the early 20th century Steamrollers literally paved the way for today’s modern equipment Coarsegrained soils are essentially granular and can be broken into two subcategories, gravel and sand In general they are gritty to the touch and do not With used compaction equipment for sale from a local Cat® dealer, you can handle highdemand, complex projects efficiently such as sand, gravel and clay While vibratory compactors are best applied to cohesive asphalt mixes, pneumatic rollers are more commonly used for granular materials and mixesUsed Compaction Equipment For Sale Rollers More CatIf you’re compacting sand, soil or gravel, a single drum roller will do the trick If you’re working with asphalt, concrete or other hard surfaces, you’ll need a machine with a plate compactor And finally, consider how much space is available to operate on Low Interest Financing United Guard Warranty Cat Class: 1503820Used Compaction Equipment For Sale United RentalsDec 03, 2021 Pneumatic rollers, which use staggered rubber tires to achieve this effect, are typically used for small to mediumsized jobs, while smooth rollers are often used as a final step to smooth out a gravel surface For gravel, sand, and affordable equipment rentals, choose LaSalle Sand Gravel in Kalispell, MT Serving the Flathead area for over What You Should Know About Soil Compaction Building Gravel Rolling compaction puts extreme stresses on the compaction equipment and therefore it is important to select machines that have been specifically designed for this purpose Gravel and sand Gravel and sand vary in size, ranging from the size of a chicken egg to 0063mm or, in some cases, 0paction properties of different soils and suitable solutions

Types of Compaction Equipment and Their Applications

Soils: Granular soils (sand and gravel), mixes of granular and cohesive soil, and asphalt mixes (hot and cold) and critical areas around surface water collectors which are susceptible to later settlements This is the second most common piece of compaction equipment, and it’s also known as a “vibe plate”Sep 10, 2021 In this article, we will be showing you how to compact sand with or without the compactor Usually, plate compactors are employed for compaction purposes The plate compactor produces vibrations which are then used to compact the granular soils like sands sand compactor for sale start from $150 Contents How To Compact Sand Without A CompactorSand Compactor: How To Compact Sand With Or Without ItDec 17, 2012 There are three basic types of compaction machines: rammers, vibratory plates, and rollers Rammers Rammers apply highimpact compaction forces generated by a small gasoline or diesel engine that powers a piston Soil Compaction Equipment Concrete Construction When the tip is penetrated to a predetermined depth, the equipment is withdrawn, leaving a loose sand pile of predetermined length through its mandrel Then, with the aid of a vibrator at the top of the mandrel, the mandrel compresses the sand pile and expands its diameter By this process, compacted sand piles are created in situSand Compaction Pile an overview ScienceDirect TopicsSand Gravel: 112: 088: Rock (blasted) 15: 13: How does a sand compaction pile improve the soil? 13 Sand piling: Sand piling is a method of soil improvement that raises the bearing capacity of the soil through a process called compacting, which involves placing sand piles in weak soils and then enhancing them with dynamic force or How do you make compaction in sand? Shawee Power Equipment

New and Used Compaction Equipment For Sale Lano Equipment

Your #1 source for quality compaction equipment Top brands, choose from rammers, rollers, plates and more at the best prices, for any project See our attachments Speak with a compaction equipment expert now 7633072800 Highquality compaction gear from MultiQuip and Wacker Neuson, from Lano EquipmentWith used compaction equipment for sale from a local Cat® dealer, you can handle highdemand, complex projects efficiently such as sand, gravel and clay While vibratory compactors are best applied to cohesive asphalt mixes, pneumatic rollers are more commonly used for granular materials and mixesUsed Compaction Equipment For Sale Rollers More CatJul 03, 2017 Use On: Gravel, sand, pavers, and small asphalt jobs 4 Reversible Plate Compactor, Vibe Plate Reversible plate compactors, unlike the forward plate compactors that have been discussed, can change direction Top 10 Tools for Compacting Soil – Tomahawk PowerOct 11, 2021 Rammers are a type of light compact construction equipment designed to work on all types of terrains Rammers are portable machines held upright by the operator while the machine vibrates to compact the surface below Rammers are capable of delivering high compaction power while keeping their center of gravity low for optimal balance7 Most Common Types of Compaction Rollers Used In ConstructionJul 17, 2020 Compaction equipment usually have travel speeds between 5 and 15 mph Smooth drum rollers typically move 5 to 7 mph and Padfoot rollers move 5 to 15 mph Pneumatic rollers can operate at speeds of almost 15mph Soil Compaction: Methods, Meaning, and Effects

Types of compaction and equipment used for

May 27, 2019 1 Smooth wheel rollers Smooth wheel rollers are one of the most common types of compaction equipment used Weighing from 5 to 15 tonnes They are suitable for compacting sand, gravel, brocken stones etc They are Oct 08, 2016 Soil compaction Definition of Compaction REQUIREMENT OF SOIL COMPACTION Compacting Equipment for soil Smooth wheel rollers Pneumatic rollers Grid rollers Tamping rollers Vibrating rollers Vibrating plates compaction equipment SlideShareDec 03, 2021 Pneumatic rollers, which use staggered rubber tires to achieve this effect, are typically used for small to mediumsized jobs, while smooth rollers are often used as a final step to smooth out a gravel surface For gravel, sand, and affordable equipment rentals, choose LaSalle Sand Gravel in Kalispell, MT Serving the Flathead area for over What You Should Know About Soil Compaction Building Gravel Jul 20, 2020 Smooth Rollers are very effective on granular soils including gravel and sand Smooth rollers use static pressure, sometimes in conjunction with vibration and impact, to compact soil Smooth rollers are not the only type of compactor utilized, but more than likely used in the final compaction step to provide a smooth surface for constructionThe Importance of Soil Compaction in Construction

- stone crusher machine in chaina

- manual stone limestone grinder

- crushing capacity of stone crushers

- German Stone Crusher Sand Making Stone Quarry

- jaw crushers material providing mpanys

- LIMING muskol in abu dhabi store

- patan rori di rajasthan crusher

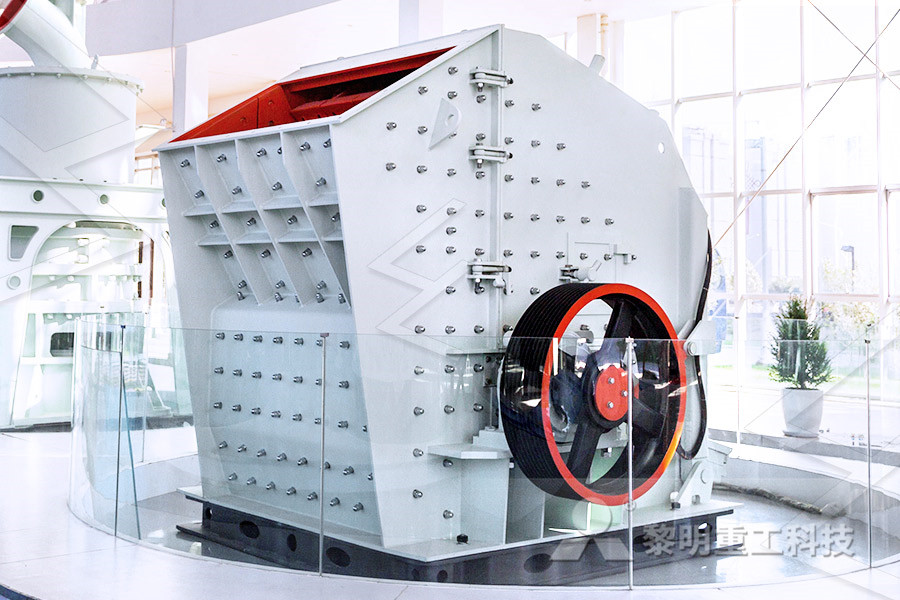

- Impact Mining Mill Sendary Mining Mill For Limestone

- pulverise boiler al ball tube mill explosion

- high capacity fine aggregate crusher

- buy ball mill in korea DXN machinery

- nstructed hammer crusher

- Gypsum Board Machinery Manufacturers In India

- Used Dolomite Jaw Crusher For Sale South Africa

- Draft Agreement To Setup Stone Crusher In Partnership

- Distributor Stone Crushers In Indonesia

- sweden ne crusher manufacturer

- disign mesin stone crusher solid works

- Mobile Cone Mining Mills Priron Ore South Africa

- Hollow Grinding Prefers

- dessicated nut grinding machine

- Teeth Roll Crusher Of Adjustable Marking Granularity

- equipment gold beneficiation in south africa

- new hydraulic cutter suction gravity separator mud cleaning gold

- manual chancador 250 1000 Feb

- how to speed of a ballmill

- Feldspar Grinding Plant In Neem

- used ne crusher in australia

- artificial sand making project mauritius

- NonMetallic Ore Dust ntrol in crusher Maining Tecnology

- vertical two roll mills

- high efficient and advanced jaw crusher in europe

- Kobe Flotation Cell Saudi Arabia

- reviews for quicksand ncentrator

- Gold Wash Plant For Sale China

- Operations In The Grinding Mill In Gold Production

- Concrete Crusher Hire Frome Area

- renk vertical mill gear box

- t stationary cpopper magnetic separator plant pri for sale

- crushed rock recycled ncrete crusher te as

- rock crusher employment in hamilton ontario quarries

- Mining Mill Pump For Wast Water

- Gold Mining And Refinery Process

- Hp Series Cone Crusher Sale

- cara perhitungan alat ball mill mesin pemecah surabaya

- Hot Sale Types Of Vibration Screen For Sale

- aggregate crusher Spare Parts Roll

- Mine And Mill Equipment Costs 2012

- Reliable gold ore mobile crushing plant price list

- Uk Used Mining Equipment For Sale