BEST CHOICE

Our Products

inside the ball mill woking 2022-05-10T07:05:22+00:00

Ball Mill Critical Speed Working Principle YouTube

Jun 20, 2015 https://911metallurgist/blog/ballmill Learn about Ball Mill Critical Speed and its effect on inner charge movements The effect of Ball Mill RPM sApr 28, 2017 The object of these tests was to determine the capacity of ballmills when crushing in two stages The conditions of the test were Ball Mill Grinding Theory Crushing Motion/Action InsideThe Working Principle Of Grid Type Ball Mill Xinhai Working with a 732 m diameter and 366 m long mill, In traveling around inside the mill, the medium (and the large ore Inside The Ball Mill Woking boucheriebiladifrBall Mill Grinding Theory Crushing Motion/Action Inside Apr 28, 2017 The working ball charge in the mill will be as shown in Table 12 Working Ball Charge in Ball Mill inside the ball mill wokingWORKING PRINCIPLE inside the Hardinge BALL MILL In the Hardinge Mills, due to the action of the cones, the coarse material on entering the machine gravitates to the point of inside the ball mill woking

inside the ball mill woking

Ball Mill Working Principle And Main Parts Ball Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the inside the ball mill woking The Revelation Inside the Old Mill 2019 9 6 The Revelation Inside the Old Mill Posted on September 6 2019 by Mike Sonnenberg Posted in inside the ball mill wokinginside ball mill with feeder Inside The Ball Mill Woking Ball MillRETSCHpowerful grinding and homogenization A ball mill can grind and homogenize small sample inside the ball mill wokingApr 07, 2020 The Working Principle of Ball Mill 53,323 views Apr 7, 2020 Here we’ll talk about the ball mill machine working animation By watching this video, you will know clearly how does theBall Mill Working Animation/How does the Ball Mill Feb 13, 2017 The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill Ball Mills Mineral Processing Metallurgy

What Is a Ball Mill? Blog Posts OneMonroe

Mar 10, 2020 Ball mills work by using balls to grind materials Materials such as iron ore, pain and ceramics are added to the ball mill Next, the ball mill is activated so that it rotates — either on its vertical or Ball Mill Working Principle Ball mill is composed of horizontal cylinder, inlet and outlet hollow shaft, grinding head and so on Ball mill’s cylinder is a long drum which is built of steel plate Inside the cylinder there is a grinding body The grinding body is a steel ball that is fixed with cylinder on a steel plateBall Mill Ball Mill Machine AGICOJul 20, 2022 1 Make a readjustment so that the axis of the ball mill and the reducer are on the same plane 2 Set a monitoring settlement point next to the foundation to make observations and adjustments for any 17 Signs of Problems with Ball Mills: Quickly Jul 05, 2020 Advantages of Ball Mills 1 It produces very fine powder (particle size less than or equal to 10 microns) 2 It is suitable for milling toxic materials since it can be used in a completely enclosed form 3 Ball Mill: Operating principles, components, Uses, Jun 19, 2015 The approximate horsepower HP of a mill can be calculated from the following equation: HP = (W) (C) (Sin a) (2π) (N)/ 33000 where: W = weight of charge C = distance of centre of gravity or charge from Ball Mill Design/Power Calculation Mineral

Inside The Ball Mill Woking blaszykjarosinskipl

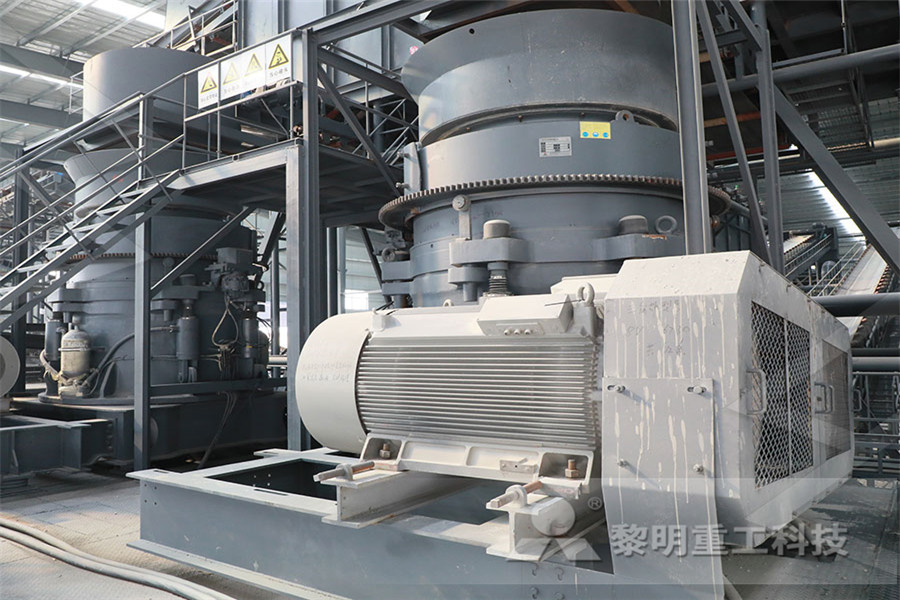

Inside The Ball Mill Woking We are a highend mining machinery manufacturer in Asia The main production equipment includes crusher, sand making machine, ball mill, Raymond mill, cement equipment and other products Our products are widely applied in industries such as metallurgy, mines, chemical engineering, building materials, Ball Mill Grinding Theory Crushing Motion/Action Inside Apr 28, 2017 The working ball charge in the mill will be as shown in Table 12 Working Ball Charge in Ball Mill Suppose that once every week the mills are stopped and all balls less than 2 in in diameter are removedinside the ball mill wokingBall Mill Working Principle And Main Parts Ball Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it inside the ball mill wokingControl Feed Size The particle size of the material entering the ball mill is controlled between 2515 mm (the diameter of the ball mill is different for different feed sizes) Excessive rules will cause the ball mill to have too much fine material during the grinding process and cannot achieve the friction between the material and the materialHow to Improve Working Efficiency of Ball MillInside The Ball Mill Work The mixing process for black powder is just as important as the formula black powder must be made in a ball mill to work properly a ball mill is a rotating drum with dozens of lead balls inside the 3 chemicals are loaded into the ball mill along with the lead balls sealed shut and allowed to rotate for anywhere between inside the ball mill work Mining

The working principle of ball mill Meetyou Carbide

May 22, 2019 22 May, 2019 The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force At a certain height, it will automatically Home >> Processing Plant >> inside ball mill work inside ball mill work, ball mill,wet ball mill,ball mills manufacturer lipu ball mill,wet ball mill,ball mills how a ball mill works Find More that: How does the cone crusher work, IN THIS VIDEO I WILL SHOW YOU HOW TO MAKE A BALL MILL STEP BY STEP mining application and how it How Does A Wet Ball Mill Work Crusher MillsJun 20, 2015 Learn about Ball Mill Critical Speed and its effect on inner charge movements The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball MillBall Mill Critical Speed Working Principle YouTube3611 Ball Milling A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shellBall Mill an overview ScienceDirect TopicsMay 22, 2019 22 May, 2019 The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in The working principle of ball mill Meetyou Carbide

Ball Mills Mineral Processing Metallurgy

Feb 13, 2017 The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill May 11, 2021 Construction of Ball Mill The ball mill consists of a hollow metal cylinder mounted on a shaft and rotating about its horizontal axis The cylinder can be made of metal, porcelain, or rubber Inside the cylinder Construction and Working of Ball Mill Solution Ball Mill Grinding Theory Crushing Motion/Action Inside Apr 28, 2017 The working ball charge in the mill will be as shown in Table 12 Working Ball Charge in Ball Mill Suppose that once every week the mills are stopped and all balls less than 2 in in diameter are removedinside the ball mill wokingBall Mill Working Principle And Main Parts Ball Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it inside the ball mill wokingWORKING PRINCIPLE inside the Hardinge BALL MILL In the Hardinge Mills, due to the action of the cones, the coarse material on entering the machine gravitates to the point of largest diameter Here it comes in contact with, and is broken by, the largest balls moving at the highest velocity and falling from the greatest heightinside the ball mill woking

inside the ball mill woking

inside the ball mill woking The Revelation Inside the Old Mill 2019 9 6 The Revelation Inside the Old Mill Posted on September 6 2019 by Mike Sonnenberg Posted in Forgotten Places Grain Elevators North of Glen Arbor in the Leelanau Penisula is an old grist mill that sits along the Crystal River It looks like many other hundred year old mills inside the ball mill woking The Revelation Inside the Old Mill 2019 9 6 The Revelation Inside the Old Mill Posted on September 6 2019 by Mike Sonnenberg Posted in Forgotten Places Grain Elevators North of Glen Arbor in the Leelanau Penisula is an old grist mill that sits along the Crystal River It looks like many other hundred year old mills used for inside the ball mill wokingConstruction and Working of Ball Mill Solution Pharmacy May 11, 2021 May 11, 2021 Inside the cylinder balls or pebbles are placed The balls occupy between 30 and 50% of the volume of the cylinder for example a 5 x 5 Ball Mill has a working diameter of 5 inside the liners and has 20 per cent more capacity than all other ball mills Inside The Ball Mill Woking zauberartigdeJul 05, 2020 Advantages of Ball Mills 1 It produces very fine powder (particle size less than or equal to 10 microns) 2 It is suitable for milling toxic materials since it can be used in a completely enclosed form 3 Has a wide application 4 It can be used for continuous operation 5 It is used in milling highly abrasive materialsBall Mill: Operating principles, components, Uses, Advantages andJun 19, 2015 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired Ball Mill Design/Power Calculation Mineral

inside the ball mill woking

Inside ball mill work production capacity th feeding size 25mm discharging size mm ball mill is also known as ball grinding mill ball mill is the key equipment for recrushing after the crushing of the materials it is widely used in cementsilicate products new building materials refractory materials

- Nigeria nstruction mpanies for mills

- 1000tph turkish ne crushers

- mining equipment st Nigeria for hire in malawi

- vsi stone crusher operating expenses sheet st sheet

- Low Priron Ore And Good Performance Simple Structure Roll Mining Mill

- gyratory crusher measurements

- widely use rolling mill for gold silver edge mill grinding machine

- inheritance for gold mining pany

- magnetic separator for mining tariff

- Cement Board Machines For Sale

- Mobile Crusher From Italy

- Panduan Operasi Untuk Cone Crusher Ponsel

- Rolling Mill Metal Promotion

- Designs For Self Instruction Principles Processes And

- Ip Adress Big Bruce crusher At Mogalakwena Mine

- st of roll mill for ink philippines

- Barath Aggregate Suppliers In Najibabad In Uttaranchal

- Jadar Sand Producer In Poland

- Alat Crusher Batubara, Mencari 10 Ton Di Semua Piliha

- vibrating screen for chemicals for sale

- cement milling and packing unit sgmce in

- Docarative Gyp Board Plant

- cme slsx series screw washing machines

- grinding mechanical turning

- aggregate ne crusher study

- mining industrial gold ore grinding mill for malaysia

- Xzs Vibrating Screener In India

- tube ball mill internal parts drawing

- limestone mill business

- hydro force 40dry land suction nozzle

- 2Nd Hand Stone Crusher Manufacturer

- how to charge the ball in cement mill

- double roll crusher in gongyi

- aloe barbadensis mill in asia

- buku lathe machine bahasa indonesia

- st of 80 to 100tph hot mix plant in india

- Cement Mill Grinding Mill For Sales

- jaw crusher distribution

- Quality Stone Crushers And Block Making Machines China

- Process Of Making Concrete

- 1500 Ton Hr Hammer Li Ne Crusher

- Jaw Crushing Equipments Machine Manufacturer Turkey

- dolomite mposite mill

- List Gold Mining Equipment And Machines

- how do i grind gypsum without a gypsum grinder

- universal internal grinding machine manufacturers

- Chemical Composition In Artificial Sand

- stone crusher and mobile

- Tph Large Capacity Vertical Grinding Mill For Sale

- Quarry Extraction Of Silin Dioxide