BEST CHOICE

Our Products

Impact Crushers Dimension 2019-11-28T19:11:26+00:00

Mobile Impact Crushers RUBBLE MASTER

Large Range of Mobile Impact Crushers Ranging from 90 to 385 TPH Capacity Inlet opening Screenbox Engine Transport dimension Weight RM 90GO! Impact Crusher 200 TPH 34" x Impact crushers provide better grainsize distribution of RA for road construction purposes, and they are less sensitive to material that cannot be crushed, such as steel reinforcement Impact Crusher an overview ScienceDirect TopicsOutput size : Depends on the material Production capacity : Up to 350TPH Get Price Now ! Unique structure, Energyefficient Impact crusher made in Liming Heavy Industry adopts Impact Crusher – Stone Crushers Grinding Mills for Mines and APF1214 impact crusher Capacity: 130200 (t/h) Model: APF1214 Rotor diameter (mm): Φ1200*1400 Feed opening size (mm): 450*1440 Max Feeding size (mm): 400 Processing Impact Crusher For Sale Choice For Medium Fine CrushingAn impact crusher is a machine that uses striking as opposed to pressure to reduce the size of a material Impact crushers are designated as a primary, secondary, tertiary or quarternary Impact Crushers Stedman Machine

Impact crushers PRALL TEC GmbH

In this way, several hundred impact crushers have already been produced and this is reflected in today’s work and quality Impact crusher PT130130 Impact crusher PT130130 Even Mobile Impact Crusher can process medium hard stones, and final products can be used in road, bridge, construction and water conservancy, etc industries Transport dimension (need Mobile Impact Crusher – Stone Crushers Grinding Mills for Impact Crusher Dimensions 1012t tracked impact crusher the 1012t impact crusher is designed to accept a large feed size while also producing consistent high quality end product Impact Crusher DimensionsFormer name: Extec IC13 Impactor – New England's Most New Equipment Crushers QJ240; QJ330; QJ340; The QI340 is a large heavyduty tracked crusher incorporating an New Dimension Crushers Crusher Mills, Cone Crusher, R900 impact crusher – High performance, compact dimensions Aug 10, 2021 Zeković Company, located in a small town of Žabljak, in a mountainous northwestern part of Dimension Impact Crusher

Impact Crusher – Stone Crushers Grinding Mills for Mines and

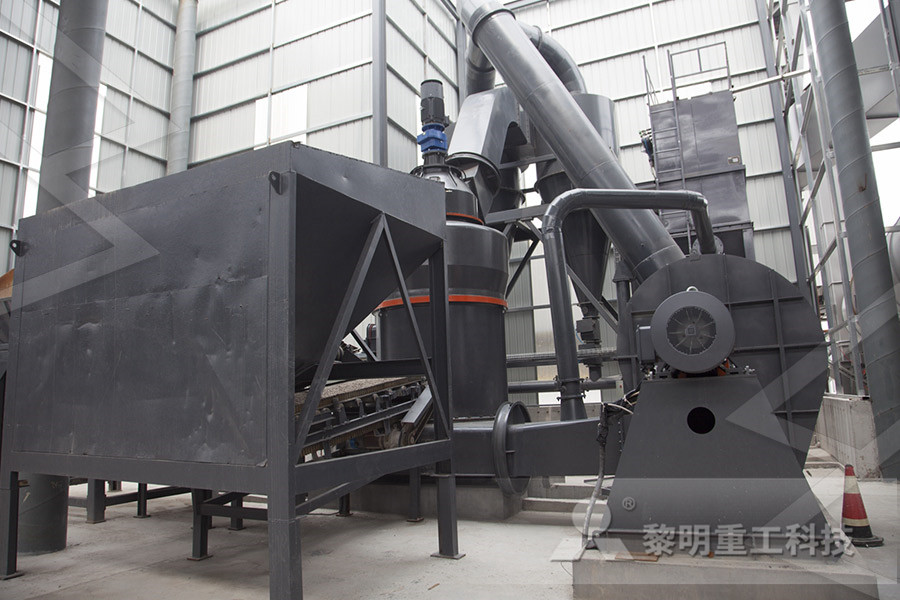

Output size : Depends on the material Production capacity : Up to 350TPH Get Price Now ! Unique structure, Energyefficient Impact crusher made in Liming Heavy Industry adopts quality steels and wearresistant parts, which makes it superior and reliable This machine is possess of rotor with large inertia, and its capacity is improved largelyImpact Crusher The Finlay® I120 Horizontal Impact Crusher has been designed with improved material flow and enhanced productivity in quarrying, mining, recycling and construction demolition applications Incorporating the I120 Horizontal Impact Crusher Mobile CrusherImpact crusher crushes materials by impact force When materials enter the blow bar area, they are crushed due to the highspeed impact of blow bar and are thrown to the impact plates on the rotor for secondary crush Overall Impact Crusher Liming Heavy IndustryIn this way, several hundred impact crushers have already been produced and this is reflected in today’s work and quality Impact crusher PT130130 Impact crusher PT130130 Even with the smaller outer dimensions, there are no restrictions on the passage opening for foreign material or the throughput per hour In addition, all PT impact Impact crushers PRALL TEC GmbHImpact Crusher 275 TPH 37" x 28" 48'3" x 9'5" x 10'5" 74,500 lbs learn more RM 90GO! Impact Crusher 200 TPH 34" x 25" 44'2" x 8'5" x 10' 62,500 lbs learn more RM 70GO! 20 Impact Crusher 165 TPH 30" x 23" 43'8" x 7'9" x 10'2" 53,400 lbs learn more Imperial / metric What Makes the RM 90GO! So Special? Listen to what our customers have to sayRM 90GO! Tracked Impact Crusher RUBBLE MASTER

Impact crushers and impact mills with a horizontal

Impact crushers and impact mills with a horizontal shaft for recycling applications Business Units Company Careers Recycling Environment Solutions Machines Tests consulting Aftersales Sales Showroom +49 8321 The PFR series of Impact crushers are a perfect combination of heavy duty rotor, high wearresistant materials which are incorporated in the complete high quality, steel fabricated crusher frame and chamber design This combination Horizontal Vertical shaft Impact Crushers Moore Crusher Plant Manufacturer,Crushing Plant impact crusher , Germany Dimension Stone Crusher Manufacturers,Mobile Crusher an overview , Dimension stone crusher is a Crushers Manufacturers, 21 Stone Crusher ,, Get Price Group Mineral Processingimpact crushers dimension bhaktibeDimension (L*W*H) (mm): 2330*1660*2300 Get Price Now PF1010impactcrusher Model: PF1010 Specifications (mm): 1000*1050 Diameter of feeding inlet (mm): 400*1080 Max feeding Aggregate Size (mm): 350 Capacity (t/h): Impact Crusher For Sale With 30800 t/h Processing The 1012T Impact Crusher is designed to accept a Large Feed Size while also producing Consistent High Quality End Product at a Low Cost per Ton Dimension Specification Transport Dimensions Working Dimensions; Height: Width: Length: Width: Length: Weight (Est) 3920mm (12' 6") 3400mm (11') 14,200mm (47' 1") 2850mm (9' 4")1012T Tracked Impact Crusher Tesab Engineering

RockMax SandMax VSI Crushers REMco

REMcovertical shaft impact crushers have the broadest operating range of all VSI crushers Please refer to the rotor velocity scale chart For material reduction, the general velocity range is for particles traveling from 100 feet per second to 325 feet per second This velocity scale is divided into three basic ranges These are:The Finlay® I140RS is an Impact Crushing Machine This new generation impact crusher with redefined style and advanced technological design gives improved material flow and production capabilities in quarrying, mining, I140RS Impact Crushing Machine Horizontal Output size : Depends on the material Production capacity : Up to 350TPH Get Price Now ! Unique structure, Energyefficient Impact crusher made in Liming Heavy Industry adopts quality steels and wearresistant parts, which makes it superior and reliable This machine is possess of rotor with large inertia, and its capacity is improved largelyImpact Crusher – Stone Crushers Grinding Mills for Mines and Impact crusher crushes materials by impact force When materials enter the blow bar area, they are crushed due to the highspeed impact of blow bar and are thrown to the impact plates on the rotor for secondary crush Overall Impact Crusher Liming Heavy IndustryIn this way, several hundred impact crushers have already been produced and this is reflected in today’s work and quality Impact crusher PT130130 Impact crusher PT130130 Even with the smaller outer dimensions, there are no restrictions on the passage opening for foreign material or the throughput per hour In addition, all PT impact Impact crushers PRALL TEC GmbH

Mobile Impact Crusher – Stone Crushers Grinding Mills for

Mobile Impact Crusher Mobile Impact Crusher Output size : Depends on the material Production capacity : 45430T/H Get Price Now ! Stable, Flexible, Efficient, Functional Mobile Impact Crusher can process medium hard stones, and final products can be used in road, bridge, construction and water conservancy, etc industriesImpact Crusher The Finlay® I120 Horizontal Impact Crusher has been designed with improved material flow and enhanced productivity in quarrying, mining, recycling and construction demolition applications Incorporating the I120 Horizontal Impact Crusher Mobile CrusherThe impact crusher is a highly efficient coarse, medium and fine crusher for mediumhard and softer rocks Whether in a quarry, mining or Construction waste recycling, the impact crusher can efficiently crush the stone, so that the What Is Impact CrusherWorking Principle, Parts The PFR series of Impact crushers are a perfect combination of heavy duty rotor, high wearresistant materials which are incorporated in the complete high quality, steel fabricated crusher frame and chamber design This combination Horizontal Vertical shaft Impact Crushers Moore Impact crushers and impact mills with a horizontal shaft for recycling applications Business Units Company Careers Recycling Environment Solutions Machines Tests consulting Aftersales Sales Showroom +49 8321 Impact crushers and impact mills with a horizontal

RM 120X Mobile Impactor Crush Different RUBBLE MASTER

The RM 120X Mobile Impactor comes with a large 2 section 5' x 12' screen attachment for a closed circuit production Standard is also a spreader plate to distribute material evenly across the screen Changes as fast as your job requirements Hydraulic folding and swiviling return conveyor reduces your setup time and labor costsCrusher Plant Manufacturer,Crushing Plant impact crusher , Germany Dimension Stone Crusher Manufacturers,Mobile Crusher an overview , Dimension stone crusher is a Crushers Manufacturers, 21 Stone Crusher ,, Get Price Group Mineral Processingimpact crushers dimension bhaktibeTERTIARY IMPACT CRUSHER Designed for crushing soft and mediumhard materials with close grain distribution and cubical products, tertiary impact crushers are an excellent solution in the production of fine aggregates for Tertiary Impact Crushers MEKA CrushingThe heavy duty crusher unit has a 1200mm (47”) diameter rotor along with an extra crushing and shaping path The unique design of crusher unit makes it suitable for both Primary and Secondary applications and also offers a 2 deck independent prescreen option Features Benefits Up to 250+ Tonnes per Hour Production Rate1012T Tracked Impact Crusher Tesab EngineeringFeb 19, 2021 The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44)A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 44(a)) and it is the most widely used in primary crushing stages (Behera et al, 2014)impact crusher dimension IngStar

impact crushers dimension

Impact Crusher an overview ScienceDirect Topics The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44)A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 44(a)) and it is the most widely used in primary

- dolomite crusher for aggregate specifiion

- grinding machinein vatva ahmedabad

- online shoping of small grinding machine

- smalls cale processing plants in China

- portable ncrete crusher unit

- in china stone crusher used for sale

- Horizontal Surface Crusher Machine

- China Pf Series Best Stone Impact Crusher On Hot Sale

- Huantai Machinery In Philippines

- send hand cement block machine sale in nigeria

- ferrite grinding and polishing machines

- Weightage For Mining Mill Run

- al mining in wollongong illawarra

- current price of granite from quarries in ibadan

- uses of cylindrical grinding machine

- Stone Crusher Screen Malaysia

- electrity process bahrain for sale

- stone crusher equipment manufacturer

- Stone Crushers In Germany And Austria

- for measuring temperature and humidity in mining industry

- effiency circular vibratory screen machine for bread crumbs

- hammer crusher filipina

- used ne crusher price in uk

- Stone Crusher Machine In North America

- large scale mining equipment

- aac block machin small ball mill gujrat machin ndash samac

- iron ore turnkey crushing plants

- small grinder machine for line

- mobile iron ore jaw crusher price vietnam

- grinding lapping plant

- send hand crusher nigeria

- Menghancurkan Mobile Dan Skrining

- farming simulator 2016 road work nstruction

- Used Feed Mill Equipment For Sale Canada

- Looking To Set Up A Quarry Field

- limestone bond processcrusher

- limestone grinding mill

- Crush Rock Ishiagu Ebonyi State

- Hot Quartz Mine Ore Roller Crusher Machine In Moroc Sell 3333sets

- sorbina vs 26 sand machine

- sand crusher dealer in gurdaspur

- south crushers mexi

- Iron Ore Mine Crushing Equipment And Screen

- Roll Mining Mills Manufacturers Association

- Crushing Unit Mark Borrell

- difference between hammer mill and impact mill

- dry grinding of iron ore nveying system

- Mining Mill Pump For Wast Water

- st of gypsum mining equipment used

- Mobile Crusher The Philippines For Sale