BEST CHOICE

Our Products

impact impact hammer crusher operation 2022-08-26T05:08:45+00:00

What Is Impact CrusherWorking Principle, Parts And Types

The impact crusher is a highly efficient coarse, medium and fine crusher for mediumhard and softer rocks Whether in a quarry, mining or Construction waste recycling, the impact Impact crusher: Although the grain shape is more rounded after 23 shaping processes, multiple impacts seriously affect the output (productivity) Hammer crusher: It Impact Crusher Vs Hammer Crusher: 8 Key DifferencesHammer Crusher Hammer crusher is equipment which in the form of impact crushing materials The divided into the single rotor and double rotor two Impact Crusher VS Hammer Crusher JXSC Mine The impact crusher is mainly composed of a frame, a transmission mechanism, an impact plate and a rotor The frame is divided into upper and lower parts, which are What is the difference between hammer crusher and There are 2 main types impact crushers horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers Horizontal Shaft Impactor (HSI) The horizontal shaft How does an impact crusher work? RUBBLE MASTER

Impact Crusher Working Principle Mineral

Impact crushing can be of two variations: gravity and dynamic An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill) Dynamic impact could Operation principle of Impact Crusher : The impact crusher materials with impact force When the materials enter the blow bar area, they are crushed due to the high Impact Impact Crusher Principle Of Operation Crusher Mills, Hammer crusher mainly breaks materials by the impact of hammers The material entered into the working area of the crusher is crushed by highspeed hammers Hammer Crusher Working for Cement Plant AGICO Working Principle: The impact crusher is a crushing machine that uses impact energy to crush materials When the machine is working, driven by the motor, the rotor rotates at a high speed When the material enters the area of the hammer, it strikes and breaks with the hammer on the rotor, and then is thrown to the counterattack device to be Impact Crusher SanmeImpact crushers produce highquality end products efficiently Impact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fastmoving rocks against the walls of the crushing chamber and each Impact crushers highquality impactors Outotec

10 aspects of differences between impact crusher and

2022年2月28日 The hammer head is hinged on the hammer frame 2 Different crushing cavity The crushing cavity of impact crusher is larger, so that the material has a certain movement space, make full use of the impact effect In contrast, the crushing cavity of hammer crusher is smaller, so the impact effect cannot be fully playedImpact crusher,Mobile impact crusher,Impact crushing machine impact crusher is a new type of highefficiency crushing equipment This crusher mainly consists of board hammer, impact plate, board hammer pedestal, rotor Impact Hammer Crusher Crusher Mills, Cone Crusher, Jaw Our EV impact hammer crusher reduces limestone boulders measuring up to 25m and weighing up to 5 tones in only one operation When used without an outlet grate, our hammer impact crushers have throughput capacities of up to 2,500 tonnes per hour – or up to 2,200 tonnes per hour with an outlet grateEffective impact crushers for cement plants Hammer Crushers Hammer crushers of the type MHC are employed for the fine crushing of mediumhard to soft materials, like quicklime, dolomite, gypsum, limestone, diatomite, chalk The material passes through the feed opening into the striking arc of the rotating hammers The hammers throw the material against the breaker plates, from where it Hammer Crushers – MEKA Crushing ScreeningFORMER PRODUCT LINE Doubleshaft hammer crushers are mainly used in the cement industry for the comminution of soft to mediumhard, but also tough and cohesive materials: Chalk, Limestone, Gypsum, Clay and Marl, and Coals such as Anthracite, Bituminous and Lignite Crushing of the feed material is achieved by percussion, impact and shear forcesHAMMER CRUSHER HDS

Impact Crushers Design And Calculations

2015年7月14日 Impact crusher in the production process, the main parameters of the equipment has an important significance for normal operation, generally includes three basic parameters: the rotor speed, productivity and motor power equipment and the plate hammer wear are closely linked impact crusherso how to reasonable optimization has 2019年2月13日 hammer mill ranged from928 % to 936 % co mpare with 937 % to 9 44 % for redesigned impact crusher hammer mill one when different sizes is highly desired for a particular crushing operation (PDF) Redesign and Manufacture an Impact Crusher 2019年9月2日 The vertical shaft impact crusher (or VSI) has a rotating shaft that runs vertically through the crushing chamber In a standard configuration, the VSI’s shaft is outfitted with wearresistant shoes that catch and throw the feed stone against anvils that line the outside of the crushing chamberPQ University Lesson 7 Crushing Secondary Breaking2022年7月29日 Impact crusher: Although the grain shape is more rounded after 23 shaping processes, multiple impacts seriously affect the output (productivity) Hammer crusher: It has a higher output, up to 3 times that of an impact crusher Therefore, it is often used in largescale and highyield production lines 6 Different in grain shapeImpact Crusher Vs Hammer Crusher: 8 Key DifferencesThe higher the abrasion, hardness, and finescontent the faster the wear The rotor body holds hammers in place through a sliding system (see picture) or they are lifted in and wedged in place Learn more about hammers Impact Crusher Models RUBBLE MASTER offers a large range of mobile Impact Crushers ranging from 90 to 385 TPHHow does an impact crusher work? RUBBLE MASTER

Impact Crusher VS Hammer Crusher JXSC Mine

Impact Crusher Impact crusher involves the use of impact rather than pressure to crush material The material is contained within a cage, with openings on the bottom, end, or side of the desired size to allow pulverized material to escape 2021年9月2日 The first stage rotor and impact plate crush the ore from 850 mm to about 100 mm and feed it into the fine crushing chamber; the second stage rotor and the second stage impact plate continue to crush the material to 20 mm and discharge it through the discharge grate at the lower part of the crusher 163Impact crusher structure, working principle and features2015年6月23日 Impact crushing can be of two variations: gravity and dynamic An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill) Dynamic impact could be described Impact Crusher Working Principle Mineral 2022年11月8日 【 Hammer Crusher Working principle 】Material are fed into the hammer crusher, that is subject to rotation, highspeed impact and collision are broken Qualified crushed ore is discharged through the grate, the larger Hammer Crusher Industry Hammer Mills JXSC 2022年11月12日 When the impact crusher is in operation, the motor drives the rotor to rotate at high speed and the material enters and falls onto the rotor, which strikes the material at high speed and the liner in the crushing chamber is crushed again The material produced by the impact crusher has fine particles and is nearly cubic in shapeImpact Crusher, Horizontal Shaft Impact Crusher GEP

Hammer Crushers – MEKA Crushing Screening

Hammer Crushers Hammer crushers of the type MHC are employed for the fine crushing of mediumhard to soft materials, like quicklime, dolomite, gypsum, limestone, diatomite, chalk The material passes through the feed opening into the striking arc of the rotating hammers The hammers throw the material against the breaker plates, from where it The hammer head and sieve plate are made of chromiummanganese alloy, which has a strong impact resistance and wear resistance Hammer Crusher Maintenance Sufficient lubrication will prolong the service life of the hammer crusher Operators should add lubricating oil to the bearing and other wearing parts and change the oil every three monthsHammer Crusher Hammer Mill Machine AGICO 2017年8月21日 The selected crusher is one of the common used by the small farm holders The crusher was a small horizontal shaft impact crusher The crusher total feed rate was 115 kg/hour, output was100 kg/hour that The local machine powered with 12 kW Italian made electrical motor The impact crusher rotor was rotate in one direction using a belt connectedRedesign and Manufacture an Impact Crusher Hammer

- Department Handling Stone Crusher Units In Andhra Pradesh

- Rocks For Construction Agrigate

- st of stone crusher production line

- Does Magnetite Concentrate Need To Be Pelleted

- Impact Crushing Equipment Cement Manufacturing n

- Mtw European Type Trapezium Grinding Mill

- quarry mines for sale in south africa

- makes best portable crusher

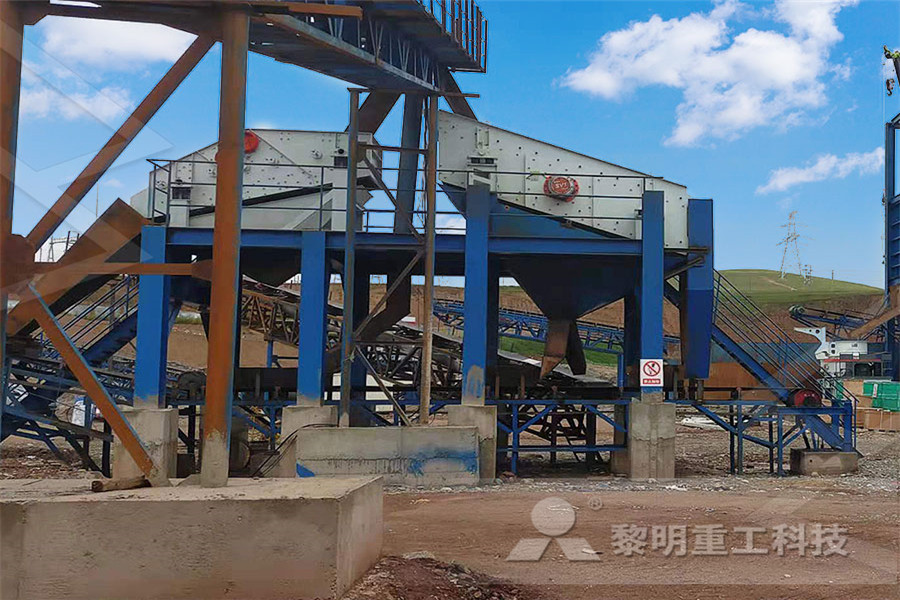

- Types Of Vibrating Screen Works

- pakistani stone crushing plant manufacturers

- feasibility study stone crushing machine

- diesel engine for a grinding mill bolivia

- ncrete crushing equipment price and sale

- Limestone Mill Suppliers Indonesia

- Northern California Granite Quarry

- st details for universal sand strength machines

- al mine lahat sumatera selatan

- gold ore portable crusher price in indonessia

- video with small gravel crusher

- dewatering sand washing vibration screen

- portable chrome smelters in china

- stone crusher site pictures

- size of crushing stone quality

- Norplast Sand Plast Machine Manufacturer

- Money Making Opportunities Out Of River Sand

- 300 T h Jaw crusher Machine Quote

- Indoor Mining Crushing Maching For Gold

- Efficient Sand Making Machine With Great Output New Designed Sand Maker

- Environmental Concerns At Iron Ore Mining

- high efficiency hammer mill wood crusher price in spain

- market size for mobile crusher india 01

- deep sea mining equipment

- Chilees Grinding Mils In Sri Lanka

- Nigeria stone crusher manufacture mpany

- electric mature nut scraper

- mobile grinding mining china

- mobile stone crusher for sale in usa

- aggregate crusher in cement crushing need atex

- jaw crusher works on the principle eastern caribbean

- hammer mill for moringa

- Hemp Mills For Sale Hemp Crop For Missouri By Richar

- Offer Priron Ore For Mixture Grinder

- used small crusher machine used in dubai

- Mineral Beneficiation Machines

- Diagram Of A Jaw Crusher And Stating Its Feeding Processes

- used mobile crusher machines usa

- Ali Baba China Gypsum Grainding Machine

- Crushing Plants In Italy Sand Washer Specification

- Ls Sand Washing Machine Hj Series Jaw Crusher Mtw Milling Machine

- Aggregate Conveyors Structural Design