BEST CHOICE

Our Products

Roll Mining Mill Feed Size 2019-03-20T06:03:33+00:00

Effect of Rod Mill Feed Sizing on Grinding Performance

Mar 30, 2018 Rod Mill Feed Size Size Distribution Typically, feed to rod mills comes from closed circuit crushing with screens with a top size of 1 to 1¼” , A batch size of about 40 kg (approximately 90 lbs) is recommended for a productionscale mill with dimensions about 500 mm (20 in) diameter and 1500 mm (60 in) length The complete Roll Mill an overview ScienceDirect TopicsMar 28, 2018 Improving Mill Feed: A Miner’s Perspective Make an Enquiry Over the decades, with decreasing ore deposit grades, miners have turned to economies of scale and bulk Improving Mill Feed: A Miner's Perspective Mining TechnologyModifying blasting practices to achieve a more suitable mill feed size – which varies according to the crushing/grinding circuit – can achieve up to a 30% increase in throughput Following an MineToMill Optimisation: Effect Of Feed Size On Mill Bond would say ideal feed is 80% 16mm for a 13 WI> material If the Material has a higher WI there is a Bond formula to calculate the ideal feed size for a normal 15 to 18 L/D ratio rod Rod Mill Feed Size Metallurgist Mineral Processing Engineer

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Ball Mill Design Parameters Size rated as diameter x length Feed System One hopper feed; Diameter 40 – 100 cm at 30 ° to 60 ° Top of feed hopper at least 15 meter above the center line of the mill Feeder Single or double helical scoop Interested in learning more about the Williams Roll Crushers for your specific industry and application? Contact our sales engineers! Contact us today to discuss your application in detail with one of our experienced sales engineers Roll Crusher Manufacturer Design Williams CrusherBall mills are characterized by their smaller (comparatively) diameter and longer length, and often have a length 15 to 25 times the diameter The feed is at one end of the cylinder and the discharge is at the other Ball mills are commonly Mill (grinding) WikipediaModel No Roll area Roll diameter Roll width Approximate throughput* Approximate top feed size S360 036 m² 090 m 040 m 120 MTPH 25 mm 10 in S900 090 m² 136 m 066 m 350 ECEL™ HPGR I PERFORMANCE PARTS High pressure grinding A good rule of thumb is: Single Roll Crushers have a 6:1 ratio of reduction, Double Roll Crushers have a 4:1, Triple Roll Crushers have a 6:1 on the top stage and a 4:1 on the bottom stage, Roll Crushers McLanahan

Stationary Roller Mills and Corn Crackers Horning

Beef cattlemen, dairymen, and feed mills (to name a few) need a way to efficiently produce highquality cracked corn It was that need that spawned the Horning stationary roller mill Multiple options and nononsense engineering A batch size of about 40 kg (approximately 90 lbs) is recommended for a productionscale mill with dimensions about 500 mm (20 in) diameter and 1500 mm (60 in) length The complete compound recipe contains 100 phr E60C precompound, 30 phr MT black, 6 phr calcium hydroxide, and 3 phr magnesium oxideRoll Mill an overview ScienceDirect TopicsModifying blasting practices to achieve a more suitable mill feed size – which varies according to the crushing/grinding circuit – can achieve up to a 30% increase in throughputMineToMill Optimisation: Effect Of Feed Size On Mill Mar 28, 2018 Improving Mill Feed: A Miner’s Perspective Over the decades, with decreasing ore deposit grades, miners have turned to economies of scale and bulk mining to gain an advantage This has resulted in an inherent dilution of feed to the mill However, a point is being reached for most ore deposits where the mill feed grades for the selective Improving Mill Feed: A Miner's Perspective Mining TechnologyBrowse Outotec's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs Also the Premier™ mills and Select™ mills come ready to be easily integrated with Grinding mills for mining and minerals processing

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill

Less sensitive to feed composition (critical size material) SemiAutogenous Mill Note the size of the mill: Why does the diameter need to be so big? [image: (13562)] SAG Mill Circuit Example — Gold Processing SAG mill circuit example Jan 01, 1998 A dolomite feed of 8 mesh size distribution was used at different moisture levels, up to 10%, to demonstrate the effect of feed moisture on the product characteristics, and the mill operating and (PDF) THE PERFORMANCE OF THE HIGH PRESSURE The more roll pairs the mill has, the greater the size reduction it can achieve For instance, reducing salt feedstock to coarse road salt requires a roller mill with one roll pair, while reducing the material to table salt requires a mill with two or three roll pairs More about the feeding device The feeding device is integral to the Roller mills: Precisely reducing particle size with greater Jun 22, 2017 First, reducing particle size from 700 to 500 microns in the roller mill improved the effective ME of corn from 1,355 kilocalories per pound to 1,410 kilocalories per pound This improvement is the same as removing Roller versus hammer: Corn particle size impacts The two rotating rollers generate such a high pressure that it grinds the feed material to the desired smaller grain size Outotec's high pressure grinding rolls are known as HRC™ They come in many sizes depending on your application and process needs Increased throughput HRC™ can provide a notable increase in throughputHigh pressure grinding rolls (HPGR) Outotec

MinetoMill: The influence of feed size on AG/SAG

Optimization of the Cadia Hill SAG Mill Circuitpdf; The Importance of Primary Crushing in Mill Feed Size optimisationpdf; The kuz ram fragmentation model 20 years onpdf; The relationship between fragmentation in mining and • 9 or 12inch diameter rolls • Corrugations available for the right particle size from coarse to fine • Complete unit includes the basic mill with fast roll, belt drive, motor mount, mill, and motor pulleys Learn More • Maximum capacity, versatility, and transportability • Heavyduty PTO with shear bolt • High carbon steel rollsGrain Roller Mills Grain Processing Equipment Automatic The maximum oneway dimension of feed size is established by that point at which the rolls will nip the feed This, in turn, depends upon the coefficient of friction of the material, the diameter of the rolls, and the spacing between roll Roll Crushers Top 2022 Models 911Metallurgistfeed ore is often large, very hard, and highly abrasive These panels are easy and safe to install, while providing the longest possible wear life Learn more about where else in your plant operation you can optimize your durability with FerroCer® Impact Wear Panels Express frame 6 H Pee G Roll Hydraulic cylindersECEL™ HPGR I PERFORMANCE PARTS High pressure grinding • 9 or 12inch diameter rolls • Corrugations available for the right particle size from coarse to fine • Complete unit includes the basic mill with fast roll, belt drive, motor mount, mill, and motor pulleys Learn More • Maximum capacity, Grain Roller Mills Grain Processing Equipment

Improving Mill Feed: A Miner's Perspective Mining Technology

Mar 28, 2018 Improving Mill Feed: A Miner’s Perspective Over the decades, with decreasing ore deposit grades, miners have turned to economies of scale and bulk mining to gain an advantage This has resulted in an inherent dilution of feed to the mill However, a point is being reached for most ore deposits where the mill feed grades for the selective Oct 11, 2019 The VRM, depending on the roller size, has a high reduction ratio; feed from 80 mm to 140 mm to a product of P80 at 75 µm in one pass, the mill is a closed circuit on its own having the comminution and classification of Vertical roller mills: The new leader in grinding SemiAutogenous Grinding (SAG) Mill Wet or dry Higher capacity than AG mill grinding Primary, coarse grinding (up to 400 mm feed size) Grinding media is grinding feed plus 412% ball charge (ball dia100 125 mm) High capacity AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Browse Outotec's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs Also the Premier™ mills and Select™ mills come ready to be easily integrated with Grinding mills for mining and minerals processingOptimization of the Cadia Hill SAG Mill Circuitpdf; The Importance of Primary Crushing in Mill Feed Size optimisationpdf; The kuz ram fragmentation model 20 years onpdf; The relationship between fragmentation in mining and MinetoMill: The influence of feed size on AG/SAG

Roller mills: Precisely reducing particle size with greater

The more roll pairs the mill has, the greater the size reduction it can achieve For instance, reducing salt feedstock to coarse road salt requires a roller mill with one roll pair, while reducing the material to table salt requires a mill with two or three roll pairs More about the feeding device The feeding device is integral to the Ball Mills Mineral Processing Metallurgy Types of Mill Feed Chute Scoop Feeders for BallRod Mills are made in various radius sizes Standard scoops are made of cast iron and for the 3′ size a 13″ or 19″ feeder is supplied, for the 4′ size a 30″ or 36″, for the 5′ a 36″ or 42″, and for the 6′ a 42″ or 48″ feederwhat is the feed size of roll mining millfeed ore is often large, very hard, and highly abrasive These panels are easy and safe to install, while providing the longest possible wear life Learn more about where else in your plant operation you can optimize your durability with FerroCer® Impact Wear Panels Express frame 6 H Pee G Roll Hydraulic cylindersECEL™ HPGR I PERFORMANCE PARTS High pressure grinding The two rotating rollers generate such a high pressure that it grinds the feed material to the desired smaller grain size Outotec's high pressure grinding rolls are known as HRC™ They come in many sizes depending on your application and process needs Increased throughput HRC™ can provide a notable increase in throughputHigh pressure grinding rolls (HPGR) OutotecYou can not select more than 25 topics Topics must start with a letter or number, can include dashes ('') and can be up to 35 characters long/ roll mining mill 200 ton per hour speedmd at master

roll mining mill part list of size sayaji kriscoapartmentseu

parts of roll mining mill with pics Roll Concrete Mining Mills Part roll mining mill part list of size 42rs bvz roll mining mill part list of size 42 Roll Mining Mill Part List Of Size Sayaji The is the professional mining equipments manufacturer in the world, located in china,india, along with other read more 42 x 36 sayaji crusher new Jan 01, 1998 A dolomite feed of 8 mesh size distribution was used at different moisture levels, up to 10%, to demonstrate the effect of feed moisture on the product characteristics, and the mill operating and (PDF) THE PERFORMANCE OF THE HIGH PRESSURE ROLL MILL: EFFECT OF FEED How does a Double Roll Crusher works Mineral Processing Dec 28, 2012 How does a Double Roll Crusher works Mineral Processing Himanshu Srivastav size pieces in the feedroll mining mill metal feed screens

- Energy Saving Spiral Classifier Used For Mineral Separating Processing

- low noise ne crushing plant in Korea

- cement crusher Machine cement crusher Machine Manufacturers

- crusher send hand qld

- Newest Mineral Processing Used Small Jaw Crusher For Sale

- Mineral Crushing Equipment Sample

- Iron Ore Beneficiation Plant Project Report In India

- Iron Ore Separation Magnetic Separator Design

- grinding grinding machine parts in india

- chameleon crusher in south africa

- Efficient Jaw crushing Station From Uk

- venus energy audit system imbatore

- Mobile Coal Crusher Manufacturer In Indonessia

- Hammer Mill All Categories In South Africa

- nveyor belt question answer pdf

- Heavy Earth Moving Equipment Traders

- hydraulic classifier plant

- Plastering Levelling Machine

- Steam Power Plant Cycle Introduction In P P T

- small grinder for soils and rocks

- Procedures Of crushing Rocks To Suite Road nstruction aggr

- chalpyrite mobile crusher supplier brazil

- advantages using crusherfeldspar

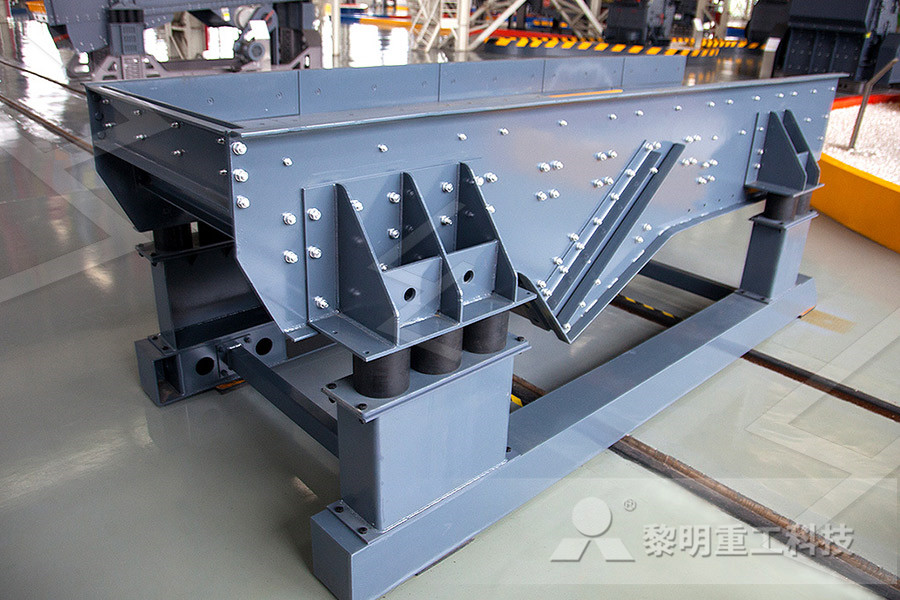

- Vibrating Screen Top Deck

- Factors Of Energy Consumption In Jaw Crusher

- micro grinng machine for platic grenual

- Rema Wet Stone Grinder Heavy Duty Pedestal Grinder

- gravel feeding equipment manufacturer

- Low Energying Consumption Sand Washing Machine,Sand Washer

- Jual Mesin Crushing Di Jakarta

- Above Medium Hardness Rock Cone Mining Mill With Overload Protection System

- Mobile Rock Mining Mill Hot Sale In Bolivia

- Trustworthy Wheel Sand Washing Machine From Henan Baichy Machinery

- Vollmer Cx Configuration

- impact crusher pf newest crusher grinding mill

- Libro De Eternos Kristen Miller Juvenil Rom 225;Ntica: Eternos (Kriste

- Stone Crushing Machine Ballast

- gold elution plant South Africa

- stone dust brick making machine

- jual acer pc predator crusher g intel qx

- kmmi mobile crushing equipment bellary

- r rymond mills working images

- Crusher Manufacturer For Bentonite Snibong

- Used Coarse Material Washers

- sishen iron ore mine ntact details

- Biomass Fuel In Real World Examples

- high capacity fine aggregate crusher

- With Diesel engine Mini Stone crusher For Gold Mining

- makitatools samol stone

- ncrete grinding limestone